starcrafttom

Active member

- Joined

- Nov 7, 2003

- Messages

- 7,972

- Reaction score

- 6

- C Dory Year

- 1984

- C Dory Model

- 27 Cruiser

- Hull Identification Number

- wn something

- Vessel Name

- to be decided later

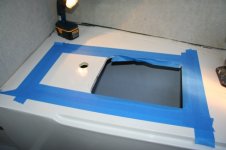

I have several projects this weekend to complete that involve me and power tools. I have to cut thru the front deck for the windlass and thru the v-berth bunk glass for biggger hatches that just came in. What is the best way to cut. I have read that I should cover the glass with tape to keep it from chipping.

I have seen pictures of folks using both jig saws and rotor type saws. Any opinon on which is better? any tips on making a smooth cut? What type of blades should I use for each? once I do something the first time I am dam near a expert, but I hate doing it the first time.

I have seen pictures of folks using both jig saws and rotor type saws. Any opinon on which is better? any tips on making a smooth cut? What type of blades should I use for each? once I do something the first time I am dam near a expert, but I hate doing it the first time.