Bill.Secure

New member

- Joined

- Aug 26, 2006

- Messages

- 118

- Reaction score

- 0

- C Dory Year

- 2007

- C Dory Model

- 25 Cruiser

- Hull Identification Number

- 25162

- Vessel Name

- Barnacle Bill

Just got my CD-25 back yesterday from Cutter after the 20hr service and some warranty work.

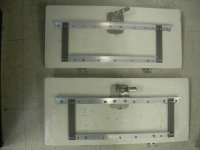

Their solution to the leaking hatches was to "grind down the hatch covers" to improve the way they fit. The surface area ground was several inches around much of the perimeter of the covers. I'll see how this solution stands the test of time and rain and report back.

Cutter hadn't been aware of this problem. They looked at another 2007 CD-25 on their lot and realized it was going to be a systemic problem on all of the CD-25s of that vintage.

I forwarded them pictures of the Meander's hatch covers so they'd have another solution in their repair arsenal if needed. I felt I needed to have the leakage addressed under warranty first before I made changes that would have caused the problem to be completely mine.

Bill

Edgewater, MD

Their solution to the leaking hatches was to "grind down the hatch covers" to improve the way they fit. The surface area ground was several inches around much of the perimeter of the covers. I'll see how this solution stands the test of time and rain and report back.

Cutter hadn't been aware of this problem. They looked at another 2007 CD-25 on their lot and realized it was going to be a systemic problem on all of the CD-25s of that vintage.

I forwarded them pictures of the Meander's hatch covers so they'd have another solution in their repair arsenal if needed. I felt I needed to have the leakage addressed under warranty first before I made changes that would have caused the problem to be completely mine.

Bill

Edgewater, MD