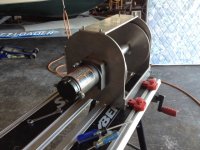

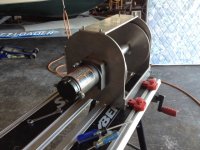

The Lori-L finally has a new aluminum anchor winch attached to the front deck. Took me most of 3 weeks working an hour or so a day to cut it out and build the drum for it. Used 5052 1/4 inch aluminum for the main structure and drum circles and 2 1/2 aluminum pipe for the center. Tacked it all together and had Rozema Boat works out in Bayview do the welding part because I don't do aluminum. The Dory had 135 feet of 3/8 rode on it already, so I extended it another 50 feet and added 18 feet of 1/4 galvanized chain to the Danforth and it still would hold another 50 I'm sure. I would rather have used 1/2 but 3/8 for this size boat will most likely work for the places we will be anchoring. Had 1/2 on both our 35 footers and the 40 in Alaska and never lost an anchor, so the 3/8 should be fine. I'm driving the winch with one of those $50.00 2000 lb 12 volt anchor winch motors attached to the starboard side directly to the drum side plates. I cut the 2000 lb aluminum winch drum in half and used them on both sides of the drum to support and drive it. I don't know how to put photos on here, but it actually turned out OK. If someone wants to tackle one I could easily email you photos of the work stages in progress. I looked for a small aluminum winch on Ebay but they were too expensive for my blood ($1300-$3000). I had made a couple hydraulic ones for our commercial boats out of aluminum and they worked fine, so I figured I would try a smaller version with 12 volt. Takes about 3 minutes to spool on the length I have but after the spool gets about half full, it speeds up considerably. Most of our anchoring will be in 15 to 20 feet of water, so won't be getting clear down to the spool anyway. (unless we get into a blow). Right now I have about $175 in it not counting several hours of my labor which I guess is not worth much anymore. I have a lathe and did use it for part of it, but it could also be done with a hole saw. They are really not that bad to build once you get it all laid out. I just cut everything out with my table saw and thin 7 inch carbide blade. Trued the drum on my lathe and it was ready for the welder.. Sure beats hand lining an anchor.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

New aluminum anchor winch just finished building

- Thread starter Sea-C

- Start date

PaulNBriannaLynn

New member

That sounds like great work! I'd love to see a picture of this finished product mounted on the boat

Sea-C

Another " thanks" for this. I'm stilling hoping someone with more tech skills than I will help you get pics up for this. It sounds like it should be there for future reference. In the meantime I'll PM you for the pics.

What motor did you use? Where did you get it? Have you used it yet? How did it work-- any changes you would make if you made another?

Thanks!!!

Another " thanks" for this. I'm stilling hoping someone with more tech skills than I will help you get pics up for this. It sounds like it should be there for future reference. In the meantime I'll PM you for the pics.

What motor did you use? Where did you get it? Have you used it yet? How did it work-- any changes you would make if you made another?

Thanks!!!

Very interesting--I would love to see photos. I am not visualizing what you did for bearings. Are there two motors? Did you use a "Superwinch"--and cut the drum of it in half? I assume that there are gears in the hub of the driving part of the motor?

Thanks

I cut the 2000 lb aluminum winch drum in half and used them on both sides of the drum to support and drive it

Thanks

To answer some of your questions about the winch, you can buy these little 2000 lb winches several different places or direct from Cal. I got mine at Costco for $49.95. $50.00 for the 5052 x 1/4 aluminum sheet which was enough to do everything if you don't make any mistakes. I don't know of anything much I would change except for using a 1 piece 3/4 inch solid spacer between the motor and drum instead of 3 1/4 inch ones. But I already had 1/4 5052 aluminum so I just turned 3 out on the lathe and used them. I haven't had the boat out because I just got done with the wiring and all. But I wound the 200 feet of rode and chain onto it and it would drag me across the shop with both feet firmly planted and hardly made any sound change to the motor. I weigh 190 and my anchor only weighs 40 or 50 lbs with the chain & rode so I don't see a problem. The motor has the gearing right in it and I believe it is about 20 to 1, but am guessing on that. I did put 5 coats of Rustoleum hammered silver on the motor though to help with the salt water. I didn't use the winch controls that come with it, however you could with much less trouble. I wired it through a 40 amp circuit breaker and a 40 amp relay and control it for up only, (not power down like the factory winch controls do because it free spools down with the use of a small brake to slow it down if need be.) I used a double throw momentary on/off/lock on switch so I could bump it a little as it comes over the bow. Everything went inside of a 3 1/2 X5X1 1/2 deep aluminum box I built and just screwed it to the cabin bulkhead right beside the winch. That is maybe another thing I might do different. It is ok but I always have problems with drilling the first holes in my boat. One major thing, alignment and spacing is critical but not at all hard if you cut the winch drum in half and use both ends to drive the new drum. Just have to make sure everything stays centered. It might be home made, but I'm not ashamed to pull into any marina with it on the bow. One thing about it, home made,,,you can make it as large or as small as you want.

My "clone project" is already stewing, few other things to finish up before I can tackle a windlass. Thank you Al for the inspiration!! That's very cool. Thank you Bob for getting pics up.

A few more questions:: Could not find the winch at Costco.com. Is it a small bumper winch for a ATV or other off-road vehicle? Did find some for that at Harbor Freight (about $150 ). Does the line wind on as evenly on its own as in the pics?? You answered my question about size of the reel and amount of line.

Do you have any more pics?? If so be nice to see.

Does anyone else have any more thoughts about using 3/8" for anchor line instead of 1/2"?? It would be harder if needed to haul in by hand if necessisary and chaffing would be a problem sooner, if it occurred.

All in all it is a great idea, well executed!

A few more questions:: Could not find the winch at Costco.com. Is it a small bumper winch for a ATV or other off-road vehicle? Did find some for that at Harbor Freight (about $150 ). Does the line wind on as evenly on its own as in the pics?? You answered my question about size of the reel and amount of line.

Do you have any more pics?? If so be nice to see.

Does anyone else have any more thoughts about using 3/8" for anchor line instead of 1/2"?? It would be harder if needed to haul in by hand if necessisary and chaffing would be a problem sooner, if it occurred.

All in all it is a great idea, well executed!

I had 300 feet of 3/8 of nylon double braid which I have owned since the mid 1960's (It may still be in the garage somewhere). I kept it and some chain in a milk crate. It was getting mighty stiff (despite washing and soaking in fabric softener), but still usable a few years back. We used that on boats from 18 to 62 feet--in the latter for kedging the boat off a dock, as a spring line. or as with a Danforth 12# HT anchor as a lunch hook.

Yes, it is a little harder on your hands, but it is plenty strong, and would be very satisfactory as an anchor line. I do prefer the double braid. I don't know if 3/8 is available in 8 plait.

Yes, it is a little harder on your hands, but it is plenty strong, and would be very satisfactory as an anchor line. I do prefer the double braid. I don't know if 3/8 is available in 8 plait.

olsurfdog: Amazon has the 2000 Champion winch just like I used for $67.00 + or- a buck or two.. Direct site address is---

http://www.amazon.com/Champion-Power-Eq ... 00lb+winch

If you use the small drum and bushings that came with the winch and lube them up super good with Silglyde GL-5( I think the number is,) they should last for quite awhile seeing as how they hold up pretty good pulling 2000 lbs and you will only be lifting 30-50 lbs. depending on your anchor gear setup. You could probably machine a bronze bushing to support the port side of the drum, but not too sure how it would fare in aluminum and salt. When the bushings wear, they are not that hard to change if you set things up the same basic way I have them. That is why the clearances are critical because you have to make it to where you can just remove 4 screws from the motor and a 3/4 spacer and the drum will slide right out the front of the winch. You will notice in the photos that the two front side guide pieces I installed just covers the edges of the drum so rode can't slide off the drum side and wrap around between the edges of the winch and jam it up. Those two cannot be welded and need to be removed so the drum can slip out. I just used three 8-32 ss Phillips head 1/2 inch screws and tapped them into the edge of the side plates so they can easily be removed. It might look like you would have trouble tapping into the edge of a piece of 1/4, but you have easily enough room if you keep things in the middle of the piece. If the only thing you have is a basic tool kit, this might not be a project you want to tackle. If you have a friend with a lathe, it really would be nice, but you will need a cheap tap and die set and set of good drill bits, plus a belt sander, vise, and a couple hole saws. (And lots of patience) Someone asked if it level wound onto the drum the way I showed it in the photo. WELL!! it actually does pretty good, but you still need to watch over it. On The C-Dories, you can easily reach any part you need right from the front hatch. ( I hope I'm not taking up too much space on the C-Brats site with this thing.) I'm fairly new to it and if I am, please someone let me know and I will back off.. I just didn't think many would be interested in it...

http://www.amazon.com/Champion-Power-Eq ... 00lb+winch

If you use the small drum and bushings that came with the winch and lube them up super good with Silglyde GL-5( I think the number is,) they should last for quite awhile seeing as how they hold up pretty good pulling 2000 lbs and you will only be lifting 30-50 lbs. depending on your anchor gear setup. You could probably machine a bronze bushing to support the port side of the drum, but not too sure how it would fare in aluminum and salt. When the bushings wear, they are not that hard to change if you set things up the same basic way I have them. That is why the clearances are critical because you have to make it to where you can just remove 4 screws from the motor and a 3/4 spacer and the drum will slide right out the front of the winch. You will notice in the photos that the two front side guide pieces I installed just covers the edges of the drum so rode can't slide off the drum side and wrap around between the edges of the winch and jam it up. Those two cannot be welded and need to be removed so the drum can slip out. I just used three 8-32 ss Phillips head 1/2 inch screws and tapped them into the edge of the side plates so they can easily be removed. It might look like you would have trouble tapping into the edge of a piece of 1/4, but you have easily enough room if you keep things in the middle of the piece. If the only thing you have is a basic tool kit, this might not be a project you want to tackle. If you have a friend with a lathe, it really would be nice, but you will need a cheap tap and die set and set of good drill bits, plus a belt sander, vise, and a couple hole saws. (And lots of patience) Someone asked if it level wound onto the drum the way I showed it in the photo. WELL!! it actually does pretty good, but you still need to watch over it. On The C-Dories, you can easily reach any part you need right from the front hatch. ( I hope I'm not taking up too much space on the C-Brats site with this thing.) I'm fairly new to it and if I am, please someone let me know and I will back off.. I just didn't think many would be interested in it...

Thanks THATAWAY for the info on the 3/8 nylon, and for putting the photos up. I sent 5 or 6 more if you got them. Pure 3/8 nylon has a tensile strength of 3240 lbs and a working load of 270 with a 12 safety factor, so it should hold up OK. I wouldn't use the combo-poly-nylon though and trust it. I guess if I'm on anchor and it starts blowing hard enough to where I think it will break a 3200 lb rope, I will fire up the kicker and jog into it all night,,,which I have done more than once in Alaska. I use my GPS anchor watch at night so as long as it don't quit on me, I should be OK.

potter water

New member

As a guy who anchors very little, I'm wondering what the advantage is to this type of windlass compared to a commercial Lewmar on the forward deck like the one on Still C-razy. Is this a cost savings thing? In terms of looks, it doesn't quite please the lines of the C-Dory. But, I will say that it obviously keeps the nasties out of the interior anchor locker. For salt water that may be a serious advantage over a conventional Lewmar/anchor locker arrangement.

I does look commercial duty. And a nice job of engineering AND saving money.

I does look commercial duty. And a nice job of engineering AND saving money.

The Braid on Braid nylon from New England ropes has a breaking strength of 4900lbs. With the 12;1 safety ratio you are a little over 400 lbs SWL. We know that these lines will take a lot more than that. I have stressed 3/8" three strand to the point the strands were fusing from the heat--and the line did not break--I suspect is was over 5,000 lbs bollard pull.

Here are some comments from C-Sea:

Some more photos:

Here are some comments from C-Sea:

I assembled the complete winch and tacked everything in place with 8-32 stainless screws so the welder could just weld it up and then remove the screws. You really don't have to do that, but I wanted to make sure he didn't change any clearances I had set up. I cut the 2000 winch right in half and fastened the ends to the drum sides with 1/4 ss flat countersink short screws. 3 on the port and 4 for the starboard. The drum sides have a hole cut just a little larger than the center of the little winch and just inserted into them and screwed fast. I inserted the original Teflon bushing into the port winch plate and that supports the port 1/2 of the outer end of the drum I cut. Fits right in but the starboard side is a little more complicated because it has to fit exactly so the motor will slide onto the drive gear. The motor bushing supports the starboard side. When yo get done, you have basically the winch like it was with a larger drum and a little modifications for the release. The release rod has to be extended exactly the same length as the width you make the drum to release the gear for free spooling through the center of the drum. If you take one of these winches apart it is pretty easy to see what I am talking about, but may sound Greek just trying to figure it out from my explanation. If someone wants to build one, I can send a photo at a time and explain what has to be done for both sides and setting up the drive from scratch.

Some more photos:

This particular winch would not be acceptable to a lot of the C-Dory owners for sure. I am kind of a commercial guy anyway and I guess the only one I have to please is me. It is simple to operate, cheap to repair and build, holds all the rode I need, and like you said, it keeps muddy bottom smell out of my boat. My Dory is a 94 and if I could afford a newer fancier one, I would probably think twice about making one and just buy one of the 2 or 3 thousand dollar ones. But I would still buy one that mounted out on the deck like a winch instead of a windless. Thanks for your comment though, they are all welcome.

The Braid on Braid nylon from New England ropes has a breaking strength of 4900lbs. With the 12;1 safety ratio you are a little over 400 lbs SWL. We know that these lines will take a lot more than that. I have stressed 3/8" three strand to the point the strands were fusing from the heat--and the line did not break--I suspect is was over 5,000 lbs bollard pull.

Here are some comments from C-Sea:

Some more photos:

Here are some comments from C-Sea:

I assembled the complete winch and tacked everything in place with 8-32 stainless screws so the welder could just weld it up and then remove the screws. You really don't have to do that, but I wanted to make sure he didn't change any clearances I had set up. I cut the 2000 winch right in half and fastened the ends to the drum sides with 1/4 ss flat countersink short screws. 3 on the port and 4 for the starboard. The drum sides have a hole cut just a little larger than the center of the little winch and just inserted into them and screwed fast. I inserted the original Teflon bushing into the port winch plate and that supports the port 1/2 of the outer end of the drum I cut. Fits right in but the starboard side is a little more complicated because it has to fit exactly so the motor will slide onto the drive gear. The motor bushing supports the starboard side. When yo get done, you have basically the winch like it was with a larger drum and a little modifications for the release. The release rod has to be extended exactly the same length as the width you make the drum to release the gear for free spooling through the center of the drum. If you take one of these winches apart it is pretty easy to see what I am talking about, but may sound Greek just trying to figure it out from my explanation. If someone wants to build one, I can send a photo at a time and explain what has to be done for both sides and setting up the drive from scratch.

Some more photos:

Thanks for posting this. Projects like this are very interesting and illustrate the wide range of talent and preferences on the site. I certainly could not tackle anything like this. One question, on which I am not clear, how is the non-motor end of the spindle supported and what do you use for a bearing surface there

Barry, that was one of my questions also which Al answered in an e-mail:

was embedded in his quote before the last (double post) of photos.

I inserted the original Teflon bushing into the port winch plate and that supports the port 1/2 of the outer end of the drum

was embedded in his quote before the last (double post) of photos.