thataway

Well-known member

- Joined

- Nov 2, 2003

- Messages

- 21,767

- Reaction score

- 118

- C Dory Year

- 2007

- C Dory Model

- 25 Cruiser

- Hull Identification Number

- DOR25652A707

- Vessel Name

- thataway

Danforth: Worked well on clay, sand, mud, and other generally soft bottoms where the anchor could get a good bite, and evenly load the flukes. However, would not set through deep grasses, such as those encountered in the Key West anchorage, and didn’t survive coral and other hard rocks where the loading on the anchor is at the tip, rather than along the entire fluke. With tip loading, and a good blow, the tip bends back on itself and the anchor is released, and will not reset.

These are valid observations and the most frequent complaints about the Danforth. The best Danforth--and what the Navy finally ended up using to pull thousands of landing craft off the beaches, is the "High Tensil anchor". I will not carry any other Danforth than the HT. The current HT 12# is rated for up to a 42 foot boat in 20 knots. The flukes inner profile is a forged "T" section--the "Standard" is bent sheet metal--that that is what bends. Also the HT has sharp edges, and will bit in, much better than the more blunt edges of the sheet metal. The HT is made of 4130 Steel, Heat Treated, Hot dipped Galvanized. I got my 12# HT in 1962 and shouldn't have sold it--but it was almost 50 years later--and still was in almost perfect condition, having been used on boats from 18' to 62' in length. A 40# HT held our Cal 46 in 90 knots of wind, and excellent holding conditions. I had to move 3x in 24 hours to keep in a protected lee as the wind shifted. A couple of years ago we were "prop dredging" the entrance to our Bayou. The boat we were using had twin 400 hp diesels. We used my 40#, WWII Danforth HT survivor to hold the boat against some loads which really stretched the 1/2" nylon rode we were using....I would guess in well over 1200# range. A fellow with a 17' whaler was supposed to pick up the anchor and bring it back to my house....He brought back the rode cut off just before the chain! Needless to say, I was a little PO, but kept my cool. We went out and worked the anchor out later in the day and I put a new splice in my 1/2" rode.

I don't think the Delta is all that good an anchor in comparison with some of the generation 3 anchors. It is a little better than the CQR, which I used extensively before the Delta and other new anchors were available. If I was younger and going to do more cruising I would get the Vulcan. or Manson Supreme/ Mantus and donate the Delta to the Hontoon auction. Incidentally the classic photo advertising the CQR in most of the US publications was taken of a boat off Avalon during a Santana wind. The boat was actually riding to a WWII Danforth HT exactly like the one I still have today.

Alma's Only, the Delta, CQR and similar anchors are not made to begin to dig in when sitting upright--you will drag them all over if you try that. They are made to roll on their side so they start to dig in...There are any number of good videos now available where the camera is secured on a floating line and float above the anchor as the boat moves back to set.

With all of these testimonies, maybe I should give the "claw" another try. Sixty Eight dollars plus shipping, at Defender!!!

One of the better tests in cohesive mud/clay was by Fortress. Their FX 37# topped out over 1800# in the 45* position, and over 900# (same as Danforth HT 35#) in the 32* position. The claw CQR and Delta were at the bottom of the test holding at in the mid 400# range. The Ronca was only 350# and the Mantus was 680#--no telling why the difference with similar anchors.

The ABYC Horizontal Working Load (lbs) Table

Wind Mode Boat ...... 20' ..25'.....30'.

speed..........length

15 Lunch Hook..... .....90 125........175..

30 Working................360 490 ......700.. Working loads

42 Storm....................500 720 .....1400

60 Violent Storm........980 1440....2800.

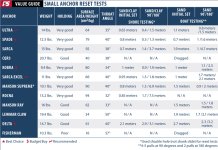

Practical Sailor small boat anchor test 20 to 25 foot sailboats, about 20# or less anchor.Observations: The downside to the Delta is that it does not dive or bury itself, "We tested two Bruce-type anchors: the Lewmar Claw and the Manson Ray. Both were defeated by the hard surface of the sand/clay seabed, as they simply skated over the surface without engaging." "Testers were surprised by their success in the sand seabed. Both quickly set well and looked as if they would dive deeper. On one pull, the Claw pulled out and would not reset, but otherwise, both completed the 90-degree and 180-degree yaw tests satisfactorily. They tended to pull out and reset at 90 degrees, rather than slide around, but in the 180-degree test, they somersaulted and reset almost immediately.

In the mud seabed, both anchors scooped large amounts of mud, which might interfere with resetting in soft bottoms"

(In 2001 Practical Sailor conclusion was: " the best test group, those that did not break out and moved very little (from not measurable to no more than 6″), were the Bruce, the Fortress FX-16, the Supermax (with the adjustable shank) and the Spade." Danforth and Fortress are both difficult to re-set if suddenly pulled out as in a 180* wind shift. They are also subject to be "fouled" with rocks, clams, etc, that keep the flukes from pivoting the 32* necessary to set in and hold.

. Mostly doing veering and 180 degree tests.

. Mostly doing veering and 180 degree tests. But tests are just that. There have been several dozen done in the last 30. years, and none agree. They do not often reproduce the reality of cruising boats. Somewhere back in the archives, I did tests when I got the Manson Boss (similar to Vulcan)--and for a 10# anchor, in our mud, clay/sand, with shells bottom did very well.