I thought I'd start a thread to document a few upgrades/projects I've got going on my 22 Cruiser, if anyone is interested (if not, please just shout me down :wink They won't be in any particular order, since boatwork seems to consist of starting five projects, moving ahead on four of them while you noodle the fifth one, then starting two more while you wait for parts for the others, then putting one on hold due to weather, then finding another four "surprise" things you should "do while you're in there," etc.

They won't be in any particular order, since boatwork seems to consist of starting five projects, moving ahead on four of them while you noodle the fifth one, then starting two more while you wait for parts for the others, then putting one on hold due to weather, then finding another four "surprise" things you should "do while you're in there," etc.  ) -- but at least they'll be mostly together in one thread.

) -- but at least they'll be mostly together in one thread.

I'll start with some detail on the anchor locker (some of which is also in the anchor-locker drain thread at the moment). The basics:

1) I had read that some 22's experienced water leaking into the V-berth from the bow, the anchor locker being one possible culprit. My boat was basically unused when I got it, so I was starting with it dry, but I wanted to keep it that way. I tried to figure out the dynamics of the leaks that existed, and after reading here (gotta love this forum!), I figured out that there were two known problems.

--One was if the drain hole was drilled too low and penetrated the locker bottom.

--The other was if there was a gap in the tabbing that connects the locker bottom with the hull side/after bulkhead, and the drain hole happened to be drilled through said gap.

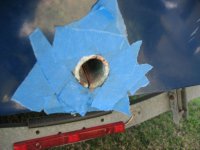

2) In looking at my anchor locker, one thing was immediately apparent: I didn't have problem #1 -- because the drain hole was a good inch or more off the bottom of the locker! I didn't fancy an inch of water/sludge accumulating, so I decided to drill a new drain hole.

I ordered a slightly larger clamshell, removed the original one, and then played around with placement of the larger one. I found that I could re-use one of the fastener holes, plus cover the original drain hole and other two fastener holes (which I would fill). I would have to hold the new hole just a tiny bit above the very bottom of the locker in order to avoid having the new clamshell "fall off" the lower edge of a strake, which I didn't want.

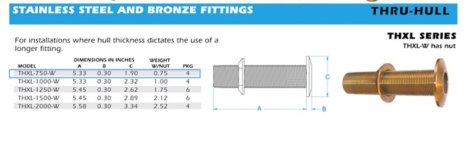

Clamshells:

Because I had the original hole to go by, I was able to drill the new hole in from the outside, so no drill gymnastics were required. I then used a file to smooth and slightly "flare" the edges of the hole on the inside of the locker, while keeping the outside just the round hole of the drill bit (basically the same size as the original hole). I did chamfer the outside of the hole slightly. I originally thought I would fill the original hole, but then I realized there was really no need to, and more drainage couldn't hurt. I filled the two clamshell-fastener holes that I wouldn't be re-using with thickened epoxy.

Next I turned to closely inspecting the two holes to see if there were any gaps where the tabbing met the hull (which could allow water to get beneath the locker bottom. I could see the line between the two sets of laminations, but nothing like a gap. Still, I loathed the idea of water leaking below, so just to be sure I prepped the holes, taped over the outside, and then coated them with neat epoxy, and subsequently with thickened epoxy (using colloidial silica). I put it on as smoothly as I can, and then to get it extra smooth I wait until it has got just slightly gummy and then smooth it with a gloved finger dipped in denatured alcohol (it doesn't take much; just a scoch keeps the glove from sticking).

The drain holes after epoxying them:

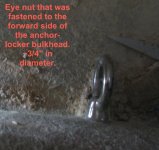

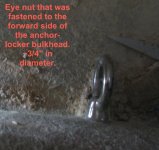

Oh, I almost forgot: There was a small nut fastened through the V-berth/anchor-locker bulkhead right near the locker bottom - obviously meant to fasten the bitter end of the anchor rode. Besides thinking it looked a bit dainty, I didn't like that it was another hole leading from the bottom of the locker into the v-berth (partway up on the cushions in this case). I also didn't know how well it was sealed and it had no backing. So I removed it (it was "sealed" with a dollop of silicone).

I don't have anything in the photo for scale, but the eye nut is probably around 3/4" in overall diameter. This is taken looking down over the bulkhead to the locker bottom. As they say, "Pardon the mess, we're remodeling"

I plan to fill/disuse the hole, but I haven't decided what to do with the bitter end of the rode yet. Thoughts are either to fasten the bitter end to a "stick" of hardwood (that can't pass through the deck hole unless it is lined up length-wise), or to put an eye nut on the backside of the bow eye (thanks to Glenda Jean for this idea).

Sunbeam :hot

I'll start with some detail on the anchor locker (some of which is also in the anchor-locker drain thread at the moment). The basics:

1) I had read that some 22's experienced water leaking into the V-berth from the bow, the anchor locker being one possible culprit. My boat was basically unused when I got it, so I was starting with it dry, but I wanted to keep it that way. I tried to figure out the dynamics of the leaks that existed, and after reading here (gotta love this forum!), I figured out that there were two known problems.

--One was if the drain hole was drilled too low and penetrated the locker bottom.

--The other was if there was a gap in the tabbing that connects the locker bottom with the hull side/after bulkhead, and the drain hole happened to be drilled through said gap.

2) In looking at my anchor locker, one thing was immediately apparent: I didn't have problem #1 -- because the drain hole was a good inch or more off the bottom of the locker! I didn't fancy an inch of water/sludge accumulating, so I decided to drill a new drain hole.

I ordered a slightly larger clamshell, removed the original one, and then played around with placement of the larger one. I found that I could re-use one of the fastener holes, plus cover the original drain hole and other two fastener holes (which I would fill). I would have to hold the new hole just a tiny bit above the very bottom of the locker in order to avoid having the new clamshell "fall off" the lower edge of a strake, which I didn't want.

Clamshells:

Because I had the original hole to go by, I was able to drill the new hole in from the outside, so no drill gymnastics were required. I then used a file to smooth and slightly "flare" the edges of the hole on the inside of the locker, while keeping the outside just the round hole of the drill bit (basically the same size as the original hole). I did chamfer the outside of the hole slightly. I originally thought I would fill the original hole, but then I realized there was really no need to, and more drainage couldn't hurt. I filled the two clamshell-fastener holes that I wouldn't be re-using with thickened epoxy.

Next I turned to closely inspecting the two holes to see if there were any gaps where the tabbing met the hull (which could allow water to get beneath the locker bottom. I could see the line between the two sets of laminations, but nothing like a gap. Still, I loathed the idea of water leaking below, so just to be sure I prepped the holes, taped over the outside, and then coated them with neat epoxy, and subsequently with thickened epoxy (using colloidial silica). I put it on as smoothly as I can, and then to get it extra smooth I wait until it has got just slightly gummy and then smooth it with a gloved finger dipped in denatured alcohol (it doesn't take much; just a scoch keeps the glove from sticking).

The drain holes after epoxying them:

Oh, I almost forgot: There was a small nut fastened through the V-berth/anchor-locker bulkhead right near the locker bottom - obviously meant to fasten the bitter end of the anchor rode. Besides thinking it looked a bit dainty, I didn't like that it was another hole leading from the bottom of the locker into the v-berth (partway up on the cushions in this case). I also didn't know how well it was sealed and it had no backing. So I removed it (it was "sealed" with a dollop of silicone).

I don't have anything in the photo for scale, but the eye nut is probably around 3/4" in overall diameter. This is taken looking down over the bulkhead to the locker bottom. As they say, "Pardon the mess, we're remodeling"

I plan to fill/disuse the hole, but I haven't decided what to do with the bitter end of the rode yet. Thoughts are either to fasten the bitter end to a "stick" of hardwood (that can't pass through the deck hole unless it is lined up length-wise), or to put an eye nut on the backside of the bow eye (thanks to Glenda Jean for this idea).

Sunbeam :hot