journey on

New member

- Joined

- Mar 3, 2005

- Messages

- 3,599

- Reaction score

- 0

- C Dory Year

- 2005

- C Dory Model

- 25 Cruiser

- Hull Identification Number

- TBD

- Vessel Name

- journey on

Well, last weekend was a busy one. We launched at Huntington Hbr, and you can read about that elsewhere, stayed at Cabrillo Beach YC, to which we belong and, the message of this thread, flooded the inside of the boat with hot water. At 1 in the morn.

So, this topic discusses what happened and how to prevent it. It applies to all C-Dory 25's and Tomcats, since they all have hot water heaters.

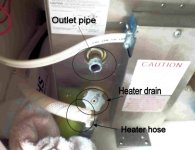

On the hot water heater outlet, there is a black fitting which goes from the heater outlet to the hot water hose. This part is polyethylene and I have found out that material is prone to failure. Replace it now with a 1/2" brass elbow and a male pipe to 1/2" hose fitting. Or you'll do it later, when you don't want to. And the replacement parts aren't available. Like we did.

Judy woke me up at midnight, saying the inside of the boat was flooded and the water was warm. She turned off the water pressure and we went looking. It turns out that black elbow on the water heater outlet had failed and was spraying water all over the cabinet. Especially on the battery charger. So I turned off the charger power and prayed it wasn't shorted.

Clean up was done by moving the carpet outside and using towels and sponges for the water. And so back to bed. The next morn, we got a ride to a hardware store, bought a pvc cap, removed the broken fitting and capped it for the weekend so we would have water pressure.

I've had to replace polyethylene fittings in our home irrigation system(s) because they crack and let water run downhill instead of watering the plants. So I know that polyethylene is prone to failure and use pvc to replace it. I've ignored it on the boat, though the fitting is in plain sight and easy to change and I got my reward. I plan to use brass, from Home Depot, since it's certainly cheaper than West Marine. It's above waterline and fresh hot water, so I suppose nylon will work.

Just change it before it fails. The battery charger came back on line, so that saved a bunch of money.

A now dry Boris

So, this topic discusses what happened and how to prevent it. It applies to all C-Dory 25's and Tomcats, since they all have hot water heaters.

On the hot water heater outlet, there is a black fitting which goes from the heater outlet to the hot water hose. This part is polyethylene and I have found out that material is prone to failure. Replace it now with a 1/2" brass elbow and a male pipe to 1/2" hose fitting. Or you'll do it later, when you don't want to. And the replacement parts aren't available. Like we did.

Judy woke me up at midnight, saying the inside of the boat was flooded and the water was warm. She turned off the water pressure and we went looking. It turns out that black elbow on the water heater outlet had failed and was spraying water all over the cabinet. Especially on the battery charger. So I turned off the charger power and prayed it wasn't shorted.

Clean up was done by moving the carpet outside and using towels and sponges for the water. And so back to bed. The next morn, we got a ride to a hardware store, bought a pvc cap, removed the broken fitting and capped it for the weekend so we would have water pressure.

I've had to replace polyethylene fittings in our home irrigation system(s) because they crack and let water run downhill instead of watering the plants. So I know that polyethylene is prone to failure and use pvc to replace it. I've ignored it on the boat, though the fitting is in plain sight and easy to change and I got my reward. I plan to use brass, from Home Depot, since it's certainly cheaper than West Marine. It's above waterline and fresh hot water, so I suppose nylon will work.

Just change it before it fails. The battery charger came back on line, so that saved a bunch of money.

A now dry Boris