The objection of Nyloc nuts is as T.R. Bauer states is that the "nylon" locking material may melt. Genuine Nyloc nuts may be OK--since they have nylon material which has a high melting temperature...I have seen some which did melt at relatively low temperature, and they are most likely a copy of the genuine Nyloc nut. (There are so many nylon insert nuts which are good, and which are bad, it is beyond the scope of this post.). Sticking with known brands, such as Nyloc is important. There are many styles of insert locking nuts--depending on the depth of the steel thread, what material is used, how deep the nut is and amount of metal threaded material in contact with the bolt or stud, the type of base etc.

ABYC is silent on the subject of Nylon insert nuts. However they do call for proper torque of the nut with lock washer. No washer should be the cables (no more than 4), the largest cable at the bottom, and moving up to smallest (consider current draw) at the top. It is permissible and often desirable to put a washer under the locking washer.

NO washer should be placed at the bottom, next to the battery case.

The cable fitting "eye" should be the same size as the hole in the flag terminal or in some cases the threaded stud, or threaded insert.

Wing nuts are not allowed on cables greater than 6 gauge in size under ABYC, because they cannot be properly torqued.

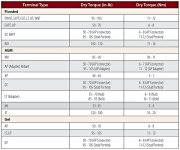

The table below shows torque on the nuts for Trojan Batteries. Such tables should be available for every battery. (in reality it is not). The torque on Nylon insert nuts should be "prevailing torque" called for, plus specific torque for that battery.

Prevailing torque, is the force needed to thread the nylon insert nut down, to where it is solidly against the washer between it and the terminals.

How many C Brats are properly torquing their nuts on battery terminals? I do carry a torque wrench (3/8 drive) in my tool kit.