You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Engine flush & shore power questions

- Thread starter jstates

- Start date

jstates

New member

- Joined

- May 23, 2006

- Messages

- 225

- Reaction score

- 0

- C Dory Year

- 2000

- C Dory Model

- 22 Cruiser

- Vessel Name

- Endurance

Bob are you saying that even when something is rated for 15 amps it may work fine on a lower amp circuit? My C-DOry Manual said the charger needed to be on a 15 amp circuit - I will check the charger and manual again when at the Marina today?

I like your idea of reversing it - I could try it - I check the boat daily especially when its raining hard - as its my first rainy season with a power boat. So if the battery wore done from running a bilge pump and the charger blew the circuit braker due to low amp - I wouldn't flood the boat.

Also how do I determine wire size - besides reading the label on the insulation - wires are very short, and stuffed way in the back under the helm seat, and then bifocals and headlamp have to fit in there also?

Jim

I like your idea of reversing it - I could try it - I check the boat daily especially when its raining hard - as its my first rainy season with a power boat. So if the battery wore done from running a bilge pump and the charger blew the circuit braker due to low amp - I wouldn't flood the boat.

Also how do I determine wire size - besides reading the label on the insulation - wires are very short, and stuffed way in the back under the helm seat, and then bifocals and headlamp have to fit in there also?

Jim

mikeporterinmd

New member

- Joined

- Sep 15, 2006

- Messages

- 645

- Reaction score

- 0

- C Dory Year

- 2002

- C Dory Model

- 22 Cruiser

- Hull Identification Number

- CD022029B202

- Vessel Name

- Shelly IV

The charger may output 15 amps at 12 volts, but I can't see how it would draw

15 amps @ 120V. Such a charger should output nearly 150 amps @ 12V.

However, the breaker for the charger can often be 15 amp if the wiring to the

charger supports 15 amp (ie: is 14 gauge or better) and the charger is designed

for a 15 amp breaker.

15 amps @ 120V. Such a charger should output nearly 150 amps @ 12V.

However, the breaker for the charger can often be 15 amp if the wiring to the

charger supports 15 amp (ie: is 14 gauge or better) and the charger is designed

for a 15 amp breaker.

jstates

New member

- Joined

- May 23, 2006

- Messages

- 225

- Reaction score

- 0

- C Dory Year

- 2000

- C Dory Model

- 22 Cruiser

- Vessel Name

- Endurance

Mike

Interesting my CDory manual said I needed 15 amp - but today I found the Guest Battery Charger Model 2610 manual [I am 3rd owner of Dory] and it indicated put a 15 amp fuse with in 6 " of the battery - it is there, and use a 5 amp circuit breaker. So as was mentioned above - they wired it wrong from the beginning switching the outlet on 5 amps with the charger on 15 amp breakers.

This has been good experience - to learn new details about the CD. Thanks to all.

Jim

Interesting my CDory manual said I needed 15 amp - but today I found the Guest Battery Charger Model 2610 manual [I am 3rd owner of Dory] and it indicated put a 15 amp fuse with in 6 " of the battery - it is there, and use a 5 amp circuit breaker. So as was mentioned above - they wired it wrong from the beginning switching the outlet on 5 amps with the charger on 15 amp breakers.

This has been good experience - to learn new details about the CD. Thanks to all.

Jim

mikeporterinmd

New member

- Joined

- Sep 15, 2006

- Messages

- 645

- Reaction score

- 0

- C Dory Year

- 2002

- C Dory Model

- 22 Cruiser

- Hull Identification Number

- CD022029B202

- Vessel Name

- Shelly IV

Right, you should have a fuse on the wires to the charger near the batteries

in case of a short. If that happened, you would have full battery current

flowing through the wires and surely start a fire.

BlueSea makes a line of 12V breakers that range up to around 150 Amps.

Waterproof, ignition proof, etc. Surface mount. Seem perfect for protecting the charger

wires if the charger outputs more than 15 amps or so.

Mike

in case of a short. If that happened, you would have full battery current

flowing through the wires and surely start a fire.

BlueSea makes a line of 12V breakers that range up to around 150 Amps.

Waterproof, ignition proof, etc. Surface mount. Seem perfect for protecting the charger

wires if the charger outputs more than 15 amps or so.

Mike

Falco

New member

- Joined

- Dec 20, 2004

- Messages

- 164

- Reaction score

- 0

- C Dory Year

- 2004

- C Dory Model

- 22 Cruiser

Re: Charlie's land based flush system: I realize this won't help anyone at the dock, but I use something similar. It's an old poly barrel, cut to height to allow water (when filled ) to cover the cavitation plate (ie all intake ports). I added 4" casters to the bottom and sealed the bolts/holes with 3M 5200. I add Salt away to the water and store the barrel full until next needed, replenishing any amount that's evaporated with new salt away. I change out the water every 3-5 flushings. This system is worth every bit of cost and effort to make. Flush muffs are a pain spew water all over the place, don't allow easy injection of Salt Away (the adapter is junk IMHO) and I don't think provide enough water to the system.

Another idea: I routinely stop off on the way home from a salt water trip at a fresh water launch ramp. I drop the rear tie downs, loosen the winch strap and back the trailer and boat in. I start up both engines for 5 min. This also washes off the back of the trailer and wheel and brakes...

As to dock flushing: here's what I would try. Use a hose fitting which screws directly into the engine. (This can be done with engines trimmed up. The port is usually just below the cavitation plate, next to the top gear case vent screw. Lower the engine (agreed w/your mechanioc running the engine in the tilt position is not a good idea. Granted the engine will still suck up some salt water, but I believe this will still help. Trim up the engine at the end, with water still going, and kill it when it's up.

Another idea: I routinely stop off on the way home from a salt water trip at a fresh water launch ramp. I drop the rear tie downs, loosen the winch strap and back the trailer and boat in. I start up both engines for 5 min. This also washes off the back of the trailer and wheel and brakes...

As to dock flushing: here's what I would try. Use a hose fitting which screws directly into the engine. (This can be done with engines trimmed up. The port is usually just below the cavitation plate, next to the top gear case vent screw. Lower the engine (agreed w/your mechanioc running the engine in the tilt position is not a good idea. Granted the engine will still suck up some salt water, but I believe this will still help. Trim up the engine at the end, with water still going, and kill it when it's up.

thataway

Well-known member

- Joined

- Nov 2, 2003

- Messages

- 21,664

- Reaction score

- 41

- C Dory Year

- 2007

- C Dory Model

- 25 Cruiser

- Hull Identification Number

- DOR25652A707

- Vessel Name

- thataway

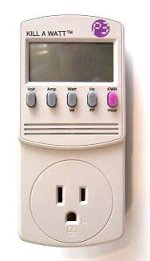

Joe, Thanks for spelling the Kill a Watt and linking to it.

As long as the current draw is less than the breaker/fues no problem using it. One can measure current draw with most digital volt meters with the meter in series with the circuit. But most meters have a second connector for the power more than half of or amp or an amp. This will be fused and is often up to 10 amps. Do your first measurement on the higher current draw setting--rather than risk damage to the meter.

I use the in line blade fuses, which have rubber holders, that can be filled with a protective grease within 6" of the batteries. I also fuse protect a circuit on the other end if it is a long run. (like by the charger). Some chargers have a circuit breaker built in. I like to corrosion protect each crimp. For higher power circuits I use the larger circuit breakers. Some of the larger fuses, one has to have a cover for the fuse and holder.

There are tables on wire sizes/vs amps/voltage drop. West Marine Catalogue has a nice one it in--and you can take last years catalogue and laminate that table to keep on the boat. An on line table is at:

http://www.rbeelectronics.com/wtable.htm

Remember that the total length of run is twice the one way--if you need 10 feet of positive wire, and 10 feet of negitive wire--the total run is 20 feet--not 10 feet. I tend to be conservative and use one size up of wire if it is near the upper end of the tables.

Also as you begin to do more electrical work around the boat, you will want to have a good pair of ratchet crimpers--use marine grade connectors--which have shrink wrap, adhesive filled tubing (a heat gun or hair dryer to shrink the tubing).

As long as the current draw is less than the breaker/fues no problem using it. One can measure current draw with most digital volt meters with the meter in series with the circuit. But most meters have a second connector for the power more than half of or amp or an amp. This will be fused and is often up to 10 amps. Do your first measurement on the higher current draw setting--rather than risk damage to the meter.

I use the in line blade fuses, which have rubber holders, that can be filled with a protective grease within 6" of the batteries. I also fuse protect a circuit on the other end if it is a long run. (like by the charger). Some chargers have a circuit breaker built in. I like to corrosion protect each crimp. For higher power circuits I use the larger circuit breakers. Some of the larger fuses, one has to have a cover for the fuse and holder.

There are tables on wire sizes/vs amps/voltage drop. West Marine Catalogue has a nice one it in--and you can take last years catalogue and laminate that table to keep on the boat. An on line table is at:

http://www.rbeelectronics.com/wtable.htm

Remember that the total length of run is twice the one way--if you need 10 feet of positive wire, and 10 feet of negitive wire--the total run is 20 feet--not 10 feet. I tend to be conservative and use one size up of wire if it is near the upper end of the tables.

Also as you begin to do more electrical work around the boat, you will want to have a good pair of ratchet crimpers--use marine grade connectors--which have shrink wrap, adhesive filled tubing (a heat gun or hair dryer to shrink the tubing).

jstates

New member

- Joined

- May 23, 2006

- Messages

- 225

- Reaction score

- 0

- C Dory Year

- 2000

- C Dory Model

- 22 Cruiser

- Vessel Name

- Endurance

Great suggestions above - thanks for the details. I do have a new tube of protective grease from Boat World but did not know how to use it - except as perhaps applied to the outside of battery terminals in my truck.

Yesterday as I opened the battery compartment - and checked all the fuses the one to the bilge pump [that had stopped working] was totally corroded and fuse blown.- the fuse holders have an orange gasket [looks like a thick rubber band] to seal out water but they are drying out, cracked and clearly not water resistant - so do I put the grease inside into the fuse contact sockets as well as outside on the drying rubber gaskets?

Also I keep the radar display at home till I need it. As a consequence when docked for a few days at the Marina I have terminal plugs [female end] that are open to salt air - do I put the grease in or on the those plugs as well. Or how do I protect them from corrosion when boat is kept in Marina?

thanks

Jim

Yesterday as I opened the battery compartment - and checked all the fuses the one to the bilge pump [that had stopped working] was totally corroded and fuse blown.- the fuse holders have an orange gasket [looks like a thick rubber band] to seal out water but they are drying out, cracked and clearly not water resistant - so do I put the grease inside into the fuse contact sockets as well as outside on the drying rubber gaskets?

Also I keep the radar display at home till I need it. As a consequence when docked for a few days at the Marina I have terminal plugs [female end] that are open to salt air - do I put the grease in or on the those plugs as well. Or how do I protect them from corrosion when boat is kept in Marina?

thanks

Jim

thataway

Well-known member

- Joined

- Nov 2, 2003

- Messages

- 21,664

- Reaction score

- 41

- C Dory Year

- 2007

- C Dory Model

- 25 Cruiser

- Hull Identification Number

- DOR25652A707

- Vessel Name

- thataway

Yes, you do want to put the grease in the fuse holder--what you describe is similar to what I have. If there is significant corrosion it is probably best to replace the fuse holder and fuse. Sort of false economy to try and clean it up for a couple of bucks costs.

I use "Corrosion Block", but Corrosion X, any of the water displacing sprays will keep corrosion from the electronics terminals. I do this when taking the electronics off the boat (long storage, or in-secure areas). Also when I hooked up the Radar pins and ground in the scanner dome, I put small amounts of corrosion block on the pins and ground connection.

I use "Corrosion Block", but Corrosion X, any of the water displacing sprays will keep corrosion from the electronics terminals. I do this when taking the electronics off the boat (long storage, or in-secure areas). Also when I hooked up the Radar pins and ground in the scanner dome, I put small amounts of corrosion block on the pins and ground connection.