Hi Mark,

It always takes me a few days (or more) to "make the boat worse" by sawing into it. But I'm guessing that you'll be like me in that once you get going, it's such a relief to have the bad stuff out, that it's almost fun (in gross, why-do-I-even-have-to-do-this way, of course). But oh it's such a joy to have it fixed right, and not have that worry.

By the way, I see in my version #2 fix, I said to "tape" the holes. Duh, I meant to write TAP. Geez. I think that's what I'd do too. I have seen people bond in metal threaded female inserts (or even female Weld Mounts), but for things I don't take in and out too often, tapped epoxy has been fine. That said, I haven't used this way on things with a lot of back-and-forth type stress. I think if it were me I'd do a few mock-ups, mix my epoxy to be very tough (you could contact WEST System and see what they recommend for a really tough thickener mixture - they are great to talk to for tech help), and then abuse the fasteners a bit and see how it holds up. On the other hand, my only worry is any back and forth "wiggle a bad tooth" type motion, and if you have a good fit and decent preload on multiple fasteners, perhaps that's not a concern. Also, if it ever did "fail," all you'd have to do is fiill it in with epoxy and re-do (the wider epoxy plug filling the hole would likely remain). I'd rather not have metal (especially stainless) buried in there if I did not have to.

I suppose a variation would be to bond in studs (I'd use bronze), but then you'd have to be able to get the furniture up and over them. Not sure if that'd be a problem. OTOH, it would be a great index vs. placing the furniture and needing to align the holes, etc. I sometimes do studs on a piece that I need to reach in and align, etc. as then I just have to "throw" the item onto the studs, then at my leisure put the nuts on.

I suppose the force on the seats can't be TOO great if what you had there held up (sort of) for this long. I mean, it's not hard to beat a pop rivet set into balsa...

I have used the tapped epoxy plug method for my trim tab planes, battery hold downs (as I needed a perfectly flush surface to slide batteries in and out due to low clearance), transducer block, and forward hatch rim. So far, so good. I noticed that Alma's Only also used this method on transom items (saw in photo album).

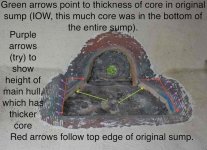

I use the Dremel #115 bit, a set of Dremel sanding drums, and the dental pick to remove core. Plus a vacuum. The drums actually work the best if I can get them in there. I try to leave as much top skin as possible (and still get in to work), as it's nice to then have the epoxy plug slide under the rim for a bit of interlock. This is for dry holes, or ones where you can easily get all the damp out. Obviously it's different for huge black/mush areas. One trick for making a pattern for new glass: I used to use cardboard, back in the day; but then I started using translucent plastic that is sold to be notebook dividers (lightly colored, with tabs). It's stiff enough to be easy to work with, and you can just place it over an irregular hole (borders of which you can then see through the plastic), and then take a Sharpie and mark a line where you want the overlap of glass to end, and voila a perfect pattern. If you are laying new glass, and want to keep the area flattish, then you'd want to grind a bevel (lower area of some removed material) of a couple of inches wide into the existing glass (then the new glass can snug down into that area/and or the fiberglass "tape" attaching your saved panel to the part you didn't cut out. (Hope that's reasonably clear?) The general guideline is that you want to bevel/tape a width of about twelve times the thickness of the skin you're fixing. So say 1/4" skin, x 12 = 3" (although since this is not an underwater hull, likely 2" is fine). A lot depends on whether you want/need the repaired area to be flush, or whether an overlay is fine.

WEST has a fantastic book if you want to read/see (drawings) how to do things. It's free. I no longer see it on paper too often (used to be at marine stores, etc.), but you can read it online or download it from the link below. Each "drawing" is a chapter of the book.

http://westsystem.com/ss/use-guides/