C-Daisy posted photos of the installation of hatches in the V-Berth on a CD22. The incremental storage is of extreme interest to us so I ordered hatches and today tackled the first part of the project. Here are some details in case anyone else is tempted by the photos in the C-Daisy sub album.

The hatch is a So-Pac Access Hatch SPA-30205 with 9 3/4" x 19 1/2" inside dimensions and 13 3/4" x 23 2/4" outside dimensions. I ordered hatches from Defender which stocks them.

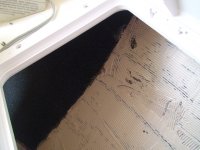

Cutting out the top of the V-Berths is easy. Digging out the foam is a bit more of a production. Crow bar, chisel and putty knife are good tools along with a long Sawzall blade in a handle. The Sawzall blade allows the foam in place to be divided up into sections making removal easier. However, it is still a fairly big task to get the foam out and you fill the V-Berth area with large and small chunks of foam. It developes static electricity and clings to everything. I put it in a bucket to transfer it to a large garbage bag and when you pour it into the garbage bag, all the tiny pieces fly back upwards and cling to the bucket. I was a bit worried that the foam would be a chore to scrape from the inside of the hull but it comes off easily with a flat tool like a putty knife.

I think that when I finish cleaning out the foam, I will fillet the inner vertical side of the V berth to the hull and tape it with some fiberglas tape epoxied into place. Further, the forward end on my boat is foam that continued across the forward end of the V-Berth. My plan is to grind the forward end smooth and then to seal it with epoxy and fiberglas cloth to provide a smooth surface and to keep the foam from continuing to crumble with abrasion. When I am all done, I will paint the interior white with Interlux Brightside so it is light and easy to clean.

All in all, a very useful addition to the boat. Thanks to all who have discussed the pros and cons over time and especially to C-Daisy for posting the pictures which inspired me to proceed.

The hatch is a So-Pac Access Hatch SPA-30205 with 9 3/4" x 19 1/2" inside dimensions and 13 3/4" x 23 2/4" outside dimensions. I ordered hatches from Defender which stocks them.

Cutting out the top of the V-Berths is easy. Digging out the foam is a bit more of a production. Crow bar, chisel and putty knife are good tools along with a long Sawzall blade in a handle. The Sawzall blade allows the foam in place to be divided up into sections making removal easier. However, it is still a fairly big task to get the foam out and you fill the V-Berth area with large and small chunks of foam. It developes static electricity and clings to everything. I put it in a bucket to transfer it to a large garbage bag and when you pour it into the garbage bag, all the tiny pieces fly back upwards and cling to the bucket. I was a bit worried that the foam would be a chore to scrape from the inside of the hull but it comes off easily with a flat tool like a putty knife.

I think that when I finish cleaning out the foam, I will fillet the inner vertical side of the V berth to the hull and tape it with some fiberglas tape epoxied into place. Further, the forward end on my boat is foam that continued across the forward end of the V-Berth. My plan is to grind the forward end smooth and then to seal it with epoxy and fiberglas cloth to provide a smooth surface and to keep the foam from continuing to crumble with abrasion. When I am all done, I will paint the interior white with Interlux Brightside so it is light and easy to clean.

All in all, a very useful addition to the boat. Thanks to all who have discussed the pros and cons over time and especially to C-Daisy for posting the pictures which inspired me to proceed.