A little background first. We have twin 40hp Hondas on the Mary Ellen. It has 120 hours on both motors ( I recently retired and hope to change this). I have always flushed the motors with muffs after use in salt water. I would say that 75% use in salt water and the other in fresh. I have never had a problem with overheating, do I need to worry about the impeller replacement? What have been others experience with twin Hondas? Also the boat is always kept on the trailer between uses. Thanks for any posts, Big Mac.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Impeller service on Honda twin 40hp

- Thread starter Big Mac

- Start date

In my experience, replace them not greater than every 4 years, 3 years to be safe. The rubber/neoprene impellers take a 'set' when they sit between uses. This set reduces their ability to pump as they turn inside the non-concentric pump housing, they cannot expand to fill the entire area on each revolution.

Sometimes they get so brittle with age that one or more impeller vanes actually break off the next time you use it, then the headaches really begin because those pieces can migrate into the cooling system and clog up the lines. Bigger $$ to retrieve them, plus the possibility of damage to the motor, better to replace, cheap insurance.

Sometimes they get so brittle with age that one or more impeller vanes actually break off the next time you use it, then the headaches really begin because those pieces can migrate into the cooling system and clog up the lines. Bigger $$ to retrieve them, plus the possibility of damage to the motor, better to replace, cheap insurance.

With 550 hours on the muddy Mississippi I finally felt guilty enough to replace impellers on my twin Honda 40's. They were in good shape except for a curvature of the vanes or "set". Never had an overheating problem but the streams were getting noticeably weak and I figured I was way overdue. My boat is left in the water 6 months each year for 6 years. I think you should be fine, just keep an eye on the streams.

An additional reason to check or replace the impellers every couple of years is to make sure the bolts holding the lower unit to the leg can be removed.

Salt corrosion can build up around the threads locking the bolts in place. The motor manuf does not lubricate or seal the bolts to prevent the sealer from oozing out and interfering with the paint job or mess up the appearance of a new motor. If a bolt breaks on removal, the shop time to drill out that bolt can add up to $100 to the service price. The tech servicing the motor should coat the bolt prior to reassembly with a sealer or antisieze or at least grease to ensure the removal next time.

The splines on the top end of the driveshaft also need to be lubricated and the only way to do this is to remove the lower unit.

Salt corrosion can build up around the threads locking the bolts in place. The motor manuf does not lubricate or seal the bolts to prevent the sealer from oozing out and interfering with the paint job or mess up the appearance of a new motor. If a bolt breaks on removal, the shop time to drill out that bolt can add up to $100 to the service price. The tech servicing the motor should coat the bolt prior to reassembly with a sealer or antisieze or at least grease to ensure the removal next time.

The splines on the top end of the driveshaft also need to be lubricated and the only way to do this is to remove the lower unit.

dogon dory

New member

Sorry, Folks - Post Deleted By Author

Actually, it is best practice to remove the lower unit at three or four year intervals to clean up and grease the splines on the drive shaft and (on some) the shift rod. That is to ensure that a few years later you'll be able to get it apart when the impeller fails. And since it is apart it would be rather foolish to not replace the rubber pieces. Really - look it up in your SAE book, and I ain't talkin' Society of Automotive.

Dan,

Has cabin fever set in already. :crook

It actually would be a good idea to have the tech who does the 20 hour service on a new motor remove the lower unit bolts one by one and coat them with the factory recommended sealer or anti-seize and replace and torque the bolts. Likewise for the thermostat housing.

If the impeller replacement is done in a shop that charges $100/hour, chasing a missing impeller blade could cost $300! more or less, depending on how much of the motor has to be dismantled. And the same owner who doesn't service the water pump regularly will wait for the motor to overheat before bringing it in for service. When I was an outboard mechanic, we called lack-of-maintenance owners---mechanics retirement plan contributors. :smileo

That old saying---pay me now or pay me more later---can be true. :wink

Stay warm,

Has cabin fever set in already. :crook

It actually would be a good idea to have the tech who does the 20 hour service on a new motor remove the lower unit bolts one by one and coat them with the factory recommended sealer or anti-seize and replace and torque the bolts. Likewise for the thermostat housing.

If the impeller replacement is done in a shop that charges $100/hour, chasing a missing impeller blade could cost $300! more or less, depending on how much of the motor has to be dismantled. And the same owner who doesn't service the water pump regularly will wait for the motor to overheat before bringing it in for service. When I was an outboard mechanic, we called lack-of-maintenance owners---mechanics retirement plan contributors. :smileo

That old saying---pay me now or pay me more later---can be true. :wink

Stay warm,

Dan,

Actual answers to your questions:

It all depends!!

If a motor is operated in silty, muddy, or glacier run off water, the impeller wears faster. Same for salt vs fresh. A black motor sitting with the lower unit in the Arizona sun when stored

will damage the impeller faster. Same with impellers in LA smog.

I have no experience with sub zero temps, but that can't be good for the rubber. It is best to use new impellers rather than old stock, but I always carried a spare WP kit and used it at the next change out.

I would change the impeller after two years and see how it has held up. Save the old impeller and label it with date and operating hours. Two years later, change again and compare.

I think the best way to keep track of water pump health is to have a pressure gauge on the dash. Then the normal operating pressure of the cooling system can be noted and monitored. If a plastic bag or kelp is picked up, it will show as reduced or no pressure. Better to find out by gauge prior to damage than wait for the overheat horn to tell you that there is already damage.

In a shop situation where the customer is paying for the work and expecting a warranty, I always changed the impeller and gaskets whether they were very worn or not. The tech in the shop doesn't know when that motor will be serviced next.

For those doing their own work, and thinking about putting the old impeller back in, ask yourself, how soon do I want to do this again? , and compare that to the cost of the parts. Always use new o-rings and gaskets, and wear plates if at all worn.

Larry H

(retired outboard mechanic)

Actual answers to your questions:

It all depends!!

If a motor is operated in silty, muddy, or glacier run off water, the impeller wears faster. Same for salt vs fresh. A black motor sitting with the lower unit in the Arizona sun when stored

will damage the impeller faster. Same with impellers in LA smog.

I have no experience with sub zero temps, but that can't be good for the rubber. It is best to use new impellers rather than old stock, but I always carried a spare WP kit and used it at the next change out.

I would change the impeller after two years and see how it has held up. Save the old impeller and label it with date and operating hours. Two years later, change again and compare.

I think the best way to keep track of water pump health is to have a pressure gauge on the dash. Then the normal operating pressure of the cooling system can be noted and monitored. If a plastic bag or kelp is picked up, it will show as reduced or no pressure. Better to find out by gauge prior to damage than wait for the overheat horn to tell you that there is already damage.

In a shop situation where the customer is paying for the work and expecting a warranty, I always changed the impeller and gaskets whether they were very worn or not. The tech in the shop doesn't know when that motor will be serviced next.

For those doing their own work, and thinking about putting the old impeller back in, ask yourself, how soon do I want to do this again? , and compare that to the cost of the parts. Always use new o-rings and gaskets, and wear plates if at all worn.

Larry H

(retired outboard mechanic)

Excellent advice Larry, experience speaks the truth -- always! I have a water pressure gauge on the dash for each engine, I note the pressure each trip. During the 5th year (yeah, I know, didn't follow my own advice) both pressures were significantly lower at low speeds, I replaced them before the next trip. That's where I came up with 4 yrs as about right -- for my usage, temperature, saltwater, smog, fresh water rinsing, hours per year, etc.....!

dogon dory

New member

Sorry, Folks - Post Deleted By Author

Dan,

I think the impellers in the newer motors will last longer than the impellers in older outboards from say the 70's or 80's. Better materials and closer manuf tolerances.

Also, customers don't know how old the dealer stock is. When I worked on Evinrudes, OMC changed the parts box design every year or so. The business owner would sell the older stock first and really old or damaged boxes got sent to the shop to be used there. Nothing wrong with the parts, the boxes just didn't look good. Newer boxes were sold over the counter.

I would buy factory parts rather than aftermarket. I have found that the factory parts are usually better quality.

Factorys want their customers to be satisfied with their motors and buy again. Same goes for O/B 2 cycle oil. Factory brand oil is good stuff. Aftermarket oil may be cheaper, but an engine overhaul is very spendy.

Larry H

I think the impellers in the newer motors will last longer than the impellers in older outboards from say the 70's or 80's. Better materials and closer manuf tolerances.

Also, customers don't know how old the dealer stock is. When I worked on Evinrudes, OMC changed the parts box design every year or so. The business owner would sell the older stock first and really old or damaged boxes got sent to the shop to be used there. Nothing wrong with the parts, the boxes just didn't look good. Newer boxes were sold over the counter.

I would buy factory parts rather than aftermarket. I have found that the factory parts are usually better quality.

Factorys want their customers to be satisfied with their motors and buy again. Same goes for O/B 2 cycle oil. Factory brand oil is good stuff. Aftermarket oil may be cheaper, but an engine overhaul is very spendy.

Larry H

Come to think of it, I've never owned an outboard that long. The one I've currently got may be the first to make it.

That's one way to eliminate maintenance expense!! :wink

Larry H

I agree Dan, I believe the impeller on a well-used (subjective term!) engine immersed often, whether salt or fresh, will last longer than if allowed to dry out for long periods (weeks/months?). Add temperature extremes to the mix, the rubber will take a beating, like you said, dry-rot. Sounds reasonable. One thing that the impeller DOESN'T see is UV from the sun.

Captains Cat

New member

I replaced the impellers in my Honda 45's several times (1994's) when I had Captain's Choice. Not a hard job. Don't try it in the water though.

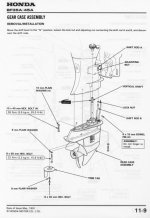

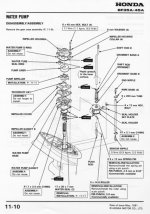

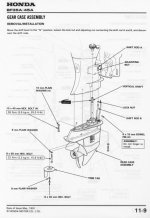

Tilt the engine all the way up, remove the 5 bolts , 4 on the sides and one at the very back under the zinc. Unscrew the shift rod, it has jam nuts on it and is on the front edge, should be able to see it. Slide the unit down and viola! it's off. The impeller is in the housing on the top. Buy the whole kit, it has gaskets, etc in it. These pix are for the 35/45's but the 40s and 50s were identical. These are in the outboards forum under pictures. There's also a complete pix history of replacement of the impeller on Almas Only Honda 90.

Charlie

Tilt the engine all the way up, remove the 5 bolts , 4 on the sides and one at the very back under the zinc. Unscrew the shift rod, it has jam nuts on it and is on the front edge, should be able to see it. Slide the unit down and viola! it's off. The impeller is in the housing on the top. Buy the whole kit, it has gaskets, etc in it. These pix are for the 35/45's but the 40s and 50s were identical. These are in the outboards forum under pictures. There's also a complete pix history of replacement of the impeller on Almas Only Honda 90.

Charlie

Our twin Honda's have 1075 hours on them in seven years of operation with no noticeable loss of water pressure. Had to change one thermostat that stuck open. Outside temperature extremes from -40 to 110 above. Used in salt and fresh water. Very difficult from where we live to have boat motors worked on by anyone but me. Sounds like I maybe way overdue or is it really this critical. Believe I will attempt the impeller replacement before our next Inland Passage Cruise.

Anyone else have twin Honda's 40's or the like with close to our hours or more with no problems with water pump. If you had water pump problems at what moter hours did it occur.

Believe in preventive maintenance. Have a l995 Dodge Intrepid with 260,000 miles that we bought new and still trust to run back and forth the 110 miles to work in extreme weather conditions. Have the water pump replaced on it each time the timing belt is replaced at 80,000 mile intervals.

Jay

Anyone else have twin Honda's 40's or the like with close to our hours or more with no problems with water pump. If you had water pump problems at what moter hours did it occur.

Believe in preventive maintenance. Have a l995 Dodge Intrepid with 260,000 miles that we bought new and still trust to run back and forth the 110 miles to work in extreme weather conditions. Have the water pump replaced on it each time the timing belt is replaced at 80,000 mile intervals.

Jay

Jay,

Be very careful in removing those lower unit bolts! It is possible to break off the SS bolts if they don't release.

If they have not been removed in seven years they may be well stuck. In the shop, we used a propane or MAP gas torch to heat the housing around the threads to expand the aluminum housing. The heat required is hot enough to smoke the paint. Be careful if you use a MAP gas torch, they get hot enough to MELT the aluminum.

Be very careful in removing those lower unit bolts! It is possible to break off the SS bolts if they don't release.

If they have not been removed in seven years they may be well stuck. In the shop, we used a propane or MAP gas torch to heat the housing around the threads to expand the aluminum housing. The heat required is hot enough to smoke the paint. Be careful if you use a MAP gas torch, they get hot enough to MELT the aluminum.

Thanks Larry---Have a gas torch and will use it. If I break one off it will be a pain. With so far to go for preventive maintance or to fix my attempt, I sometimes hesitate to long before doing needed work and those shop manuels leave a lot to be desired. Always easier the 2nd or third time. At times it seems the longer I work the bigger the job grows.

Jay

Jay

Captains Cat

New member

Larry H":2a6acnuk said:Jay,

Be very careful in removing those lower unit bolts! It is possible to break off the SS bolts if they don't release.

If they have not been removed in seven years they may be well stuck. In the shop, we used a propane or MAP gas torch to heat the housing around the threads to expand the aluminum housing. The heat required is hot enough to smoke the paint. Be careful if you use a MAP gas torch, they get hot enough to MELT the aluminum.

There are FIVE bolts too! I didn't find the one under the zinc on the tail end until I had "tapped" on it with a hammer and broke the aluminum cavitation plate! Fortunately, it was the old lower end I was replacing with Bill and El's blown power head engine lower end but it would have been bad if it wasn't! Mine came off easily after I took out all the bolts :cry and it probably hadn't been off EVER (1994-2005)!!

Charlie

Chalrie

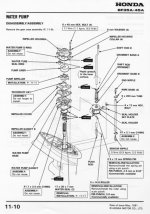

After finally getting the kits for impellor replacement on the Mary Ellen and the generous offer of a Honda shop manuel from Darrel of Lucky Fin I recently tackled this job.

The Mary Ellen is a 2001 with only 135 hours. I retired recently so that will change. A little background on usage. We use the boat mostly in Puget Sound with about 10% other use in the Columbia or local lakes. I always flush the engine after salt water use and the boat is on the trailer and in a shop when not in use. I have used SaltAway once last year.

When I took the lower units off I had no problems with getting the bolts out, although they were very dry. I use some anti-seize when I re-assembled. The impellors looked OK, but had some very obvious cracking starting on the back side of the set on the blades. I think it was a good idea to have changed them out. I also noticed a stronger pee when I did a run test yesterday on the trailer. The only trouble I had was getting the impellor over the woodrift key that wanted to slip of the slaft. I used a small amount of grease to hold it in place. The second lower unit went easier than the first. How do you others deal with the woodrift key?

I also changed out the Honda / Racor fuel filter water separator filters and they needed it. They were about 2 years old. Now all I need is a little break in the weather and off we go. Hope to see some of you at the SBS, Big Mac.

The Mary Ellen is a 2001 with only 135 hours. I retired recently so that will change. A little background on usage. We use the boat mostly in Puget Sound with about 10% other use in the Columbia or local lakes. I always flush the engine after salt water use and the boat is on the trailer and in a shop when not in use. I have used SaltAway once last year.

When I took the lower units off I had no problems with getting the bolts out, although they were very dry. I use some anti-seize when I re-assembled. The impellors looked OK, but had some very obvious cracking starting on the back side of the set on the blades. I think it was a good idea to have changed them out. I also noticed a stronger pee when I did a run test yesterday on the trailer. The only trouble I had was getting the impellor over the woodrift key that wanted to slip of the slaft. I used a small amount of grease to hold it in place. The second lower unit went easier than the first. How do you others deal with the woodrift key?

I also changed out the Honda / Racor fuel filter water separator filters and they needed it. They were about 2 years old. Now all I need is a little break in the weather and off we go. Hope to see some of you at the SBS, Big Mac.

Anyone else have twin Honda's 40's or the like with close to our hours or more with no problems with water pump. If you had water pump problems at what moter hours did it occur.

I have a single Honda 40 (1999). After noticing a reduced stream (no idea of how many hours since last change), replaced impeller with full kit- including wear plates and all gaskets. Now the impeller seems to fail every year-last change was done by Honda service..

Any thoughts on what may be causing the high frequency of failures?

I have a single Honda 40 (1999). After noticing a reduced stream (no idea of how many hours since last change), replaced impeller with full kit- including wear plates and all gaskets. Now the impeller seems to fail every year-last change was done by Honda service..

Any thoughts on what may be causing the high frequency of failures?