Hi folks,

I'd like to remove the fuel that's in my tanks right now (and have had reason to want to do it in the past as well). Siphoning or pumping with a motor bulb hasn't worked all that well in the past, so I'd like to set up a system with an electric fuel pump that I can use from time to time.

(Getting a siphon hose down into the bottom of the fuel tanks through the fills doesn't work very well, and siphoning from the "back" can't overcome the air in the fuel/water separator.)

Since I don't want to blow up, I'd like to check in with you all to see if my proposed system will be okay.

I have a Honda quick connect fitting on one of the "outbound" ports on my Racor filter, and the Racor filter is just ahead of the cable boot in the splashwell, so this will all be outside the boat.

I'm basing my plan off of this one used by DaNag (who, as far as I know, is still with us )

)

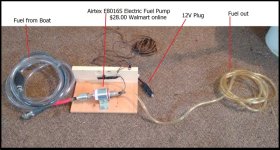

I just completed a nifty way to address this, with very little muss/fuss. I ordered up a Carter fuel pump - known in automotive circles for their quality and longevity. It comes with a bracket, and input/output nipples for 3/8" fuel line.

The pump is portable, with the bracket attached to a piece of wood. When in use, I set it down low between the tanks. I ran the IN line to a quick disconnect fitting that attaches to my Racor filter/separator, and the OUT line simply goes out my drain plug hole in the back of the boat, into a receptacle on the ground. Power is handled via aligator clips at the battery, with a switch inline to avoid sparks when connecting.

It's not super fast, probably around 2 gallons a minute...but works great.

Based on this, I plan to order the same pump as he did (Carter P4070). I'll use a length of fuel hose from the Honda quick connect on the Racor to the pump, then another from the pump to a portable gas can on the ground (pump would be outside the boat, mounted to a board). For wiring I figured I'd use a length of 10/2 I have that is about 20' long to a battery that is.... 20' away!, and then use a Blue Sea ignition protected switch that I have as a spare sitting around.

The pump does not mention being ignition protected, but I see that one of its typical uses is to transfer fuel from aircraft to barrel, out of boat tanks, etc. But... I don't want to blow up either. This will be outside the boat, and in a pretty well ventilated space, but is it okay?

When doing this, what about the fact that the hose will be going into the open top of the fuel jug. Is there a need to "seal" that opening? How far should the pump be from the opening? (It will be downhill from the Racor to the pump to the fuel container, since the boat is on the trailer.)

I want to have a setup I can use in future, so while it doesn't need to be a professional constant-duty type thing, I want it to be safe and don't need it to be the cheapest possible thing (the Carter pump is around $50 vs. the $10 pumps I also found on Amazon).

I have plenty of fuel hose (left over from when I did the new fuel hose on my boat), plus fittings, wire, and the switch.

Thanks for any input. (I've read other threads on this but still wasn't sure about the details so figured I'd ask.)

Thanks,

Sunbeam

I'd like to remove the fuel that's in my tanks right now (and have had reason to want to do it in the past as well). Siphoning or pumping with a motor bulb hasn't worked all that well in the past, so I'd like to set up a system with an electric fuel pump that I can use from time to time.

(Getting a siphon hose down into the bottom of the fuel tanks through the fills doesn't work very well, and siphoning from the "back" can't overcome the air in the fuel/water separator.)

Since I don't want to blow up, I'd like to check in with you all to see if my proposed system will be okay.

I have a Honda quick connect fitting on one of the "outbound" ports on my Racor filter, and the Racor filter is just ahead of the cable boot in the splashwell, so this will all be outside the boat.

I'm basing my plan off of this one used by DaNag (who, as far as I know, is still with us

I just completed a nifty way to address this, with very little muss/fuss. I ordered up a Carter fuel pump - known in automotive circles for their quality and longevity. It comes with a bracket, and input/output nipples for 3/8" fuel line.

The pump is portable, with the bracket attached to a piece of wood. When in use, I set it down low between the tanks. I ran the IN line to a quick disconnect fitting that attaches to my Racor filter/separator, and the OUT line simply goes out my drain plug hole in the back of the boat, into a receptacle on the ground. Power is handled via aligator clips at the battery, with a switch inline to avoid sparks when connecting.

It's not super fast, probably around 2 gallons a minute...but works great.

Based on this, I plan to order the same pump as he did (Carter P4070). I'll use a length of fuel hose from the Honda quick connect on the Racor to the pump, then another from the pump to a portable gas can on the ground (pump would be outside the boat, mounted to a board). For wiring I figured I'd use a length of 10/2 I have that is about 20' long to a battery that is.... 20' away!, and then use a Blue Sea ignition protected switch that I have as a spare sitting around.

The pump does not mention being ignition protected, but I see that one of its typical uses is to transfer fuel from aircraft to barrel, out of boat tanks, etc. But... I don't want to blow up either. This will be outside the boat, and in a pretty well ventilated space, but is it okay?

When doing this, what about the fact that the hose will be going into the open top of the fuel jug. Is there a need to "seal" that opening? How far should the pump be from the opening? (It will be downhill from the Racor to the pump to the fuel container, since the boat is on the trailer.)

I want to have a setup I can use in future, so while it doesn't need to be a professional constant-duty type thing, I want it to be safe and don't need it to be the cheapest possible thing (the Carter pump is around $50 vs. the $10 pumps I also found on Amazon).

I have plenty of fuel hose (left over from when I did the new fuel hose on my boat), plus fittings, wire, and the switch.

Thanks for any input. (I've read other threads on this but still wasn't sure about the details so figured I'd ask.)

Thanks,

Sunbeam