I'm proud to announce the Wallas 1300 Heater installation is now complete -- with a few cuts and some very sore muscles thrown in (working upside down inside the back of a cabinet). I documented several of the key areas in

My Photos (or in the

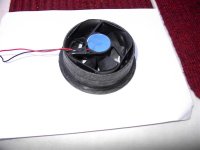

Detail Photos section). This unit is a quality product just like their 1 and 2 burner stoves, very tightly packed in a compact package -- so small, it looks like something built for a spacecraft!

For those interested, here's a quick run-down on what I did. On a scale of 1-10 (10 being most difficult), I'd say this installation was about an 8.5 -- not particularly due to the heater, but rather where I chose to locate it. I didn't want it to take away any usable space if possible and not be an eyesore either. Under the galley cabinet seemed plausible since this unit remains cool to the touch, except for the intake/exhaust tubing at sharp bends, and there are no flames or accessibility of the combustion chamber from the cabin.

The most difficult part was locating the unit in 'exactly' the right spot to 1) Allow 8-9" of 'gooseneck' from the side thru hull intake/exhaust fitting to the highest point of the connected tube into to heater unit; and 2) Allow the maximum of 3 ft of ducting to reach a suitable spot to mount the output heat register. I wanted the heat flow to be directed to the center of the cabin and the intake cold air from the floor, both achieved.

Bending the dual SS intake/exhaust tube was hefty, difficult and a 'must wear heavy gloves' situation -- that explains my cuts before the gloves went on... Took me about 2 hrs to bend it for best fit BEFORE installing it together with everything else. Where I put it required that the bracket holding the unit to the plywood glued to the wall be screwed in place at the same time as the intake/exhaust tube and attaching the heater to the bracket all be done simultaneously! That was tough. Also fabricated a heat shield at the first bend out of the heater to avoid overheating the fiberglass above or the trunk wiring nearby, used 1/4" standoffs on top of the shield to space it off the fiberglass.

I decided to parallel another 30 ft of 2-cond 8 AWG wire from the battery switch to the windlass while adding a tap under the galley to supply the Wallas with hefty juice. When I calculated the original windlass wiring gauge, I didn't do a good job accounting for the extra wire needed for all the routing to/from various points, in short, the wire gauge chosen should have been 6 AWG, so paralleling another 8 AWG provided the extra copper needed. BTW, that 30 ft of wire is about $130 -- ouch...

I had to cut a 3" hole in the shelf between the upper and lower cabinet areas to get the return air through to the heater from the bottom of the cabinet mounted intake register. This hole also served as a good route for the intake and return tubes to the fuel resevoir. Important note from the Wallas installation instructions -- make sure there are no droops/loops on the return fuel line (black) from the heater to the resevoir, will cause blockage and erratic operation of the heater.

Lastly I added a Wallas remote switch with a LED in the switch that mimics the light on the heater unit to indicate combustion in progress. The remote switch comes with about 25 ft of 4 conductor wire for 'very remote' locations. I cut it down to about 4 ft to match my location. It had to be cut anyway though to feed it through the rubber grommet in the bottom of the heater to the circuit board just inside the rear panel (requires unscrewing the rear panel and tilting out just enough to plug in the 4 conductor connector). No instructions came with this switch, but was fairly intuitively obvious. I called Scan Marine and asked if the main switch should be ON or OFF for the remote switch to work, they didn't know. Afterwards I told them OFF works just fine!

After all was completed, I checked over everything one more time, took a deep breath, sat back and flipped the remote switch ON. Woah, it came to life...! I intently watched as the fuel inched its way up the translucent intake tube to the main unit, about 1 inch a second for the 4 ft it had to go. Then a few other sounds and bingo, heat began coming out. I ran outside and down to the ground and felt the exhaust heat coming out beautifully with only a very slight hint of a kerosine odor (Klean Heat by Klean Strip has a very low odor to start with). I measured 5.0 amps during startup, about 3-4 minutes (the manual said 4.0 amps I believe), and 0.4 amps during operation. Incredibly low current and very quiet operation. The airflow is great, quite substantial, it easily fills the cabin with warm air -- a little unfair assessment though, it was only about 50-55 deg at the time.

I let it run for over an hour (this is midnight to 1am BTW on a night I have to get up for work at 6:30am), I wanted to get past the infamous "30 minute syndrome" I've read about from some folks on their stoves. For me, it was just short of a religious experience to watch that Wallas work so efficiently, clean and quiet. All I can say is wow, well worth the effort and cost. :thup

Costs: $850 heater unit, $20 fuel tank (1.5 gal), $95 combo intake/exhaust lead thru hull fitting (SS and sealed), $75 Remote Control Switch, $30 for 3" heat output register, $60 for 3 ft of SS intake/exhaust tubing and $12 for output heat duct and some shipping/handling. Total: $1,150 (bandaids not incl).