| View previous topic :: View next topic |

| Author |

Message |

Grazer

Joined: 16 Dec 2011

Posts: 183

City/Region: Yukon

State or Province: YT

C-Dory Year: 2004

C-Dory Model: 22 Cruiser

Vessel Name: C-Horse

Photos: Grazer

|

Posted: Fri Jan 31, 2014 10:07 pm Post subject: Epoxy bonding to Gelcoat Posted: Fri Jan 31, 2014 10:07 pm Post subject: Epoxy bonding to Gelcoat |

|

|

Hello All.

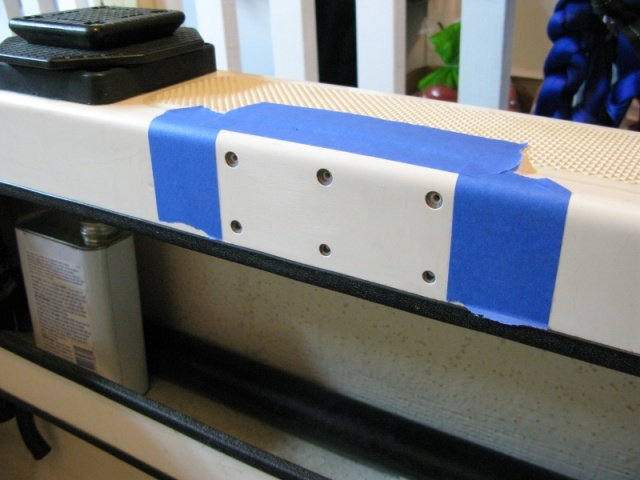

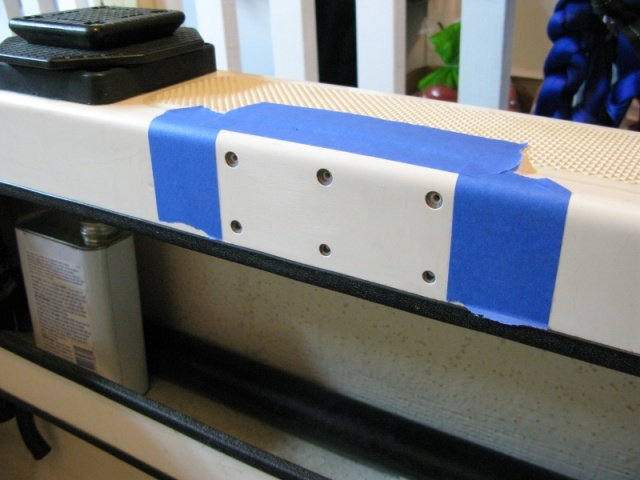

I am looking at fastening a Scotty Sidewinder Rod Holder http://www.scotty.com/fishing-gear-equipment/rod-holders/sidewinder.htm to my cockpit gunnels on inboard side. The top screws will go into the cored deck and the bottom fasteners will be through bolted. I want to protect core by sealing with epoxy, so I am considering bonding the entire bottom of the trigger lock assembly to the gunnel. This would dramatically increase the strength of the attachment. My question is, should one simply rough up the gelcoat with some 60-80 grit sandpaper and then clean with solvent and bond with epoxy OR should the gelcoat be removed entirely down to the fiberglass before bonding with epoxy? This is the area I am talking about.

<img src="http://www.c-brats.com/modules.php?full=1&set_albumName=album1897&id=IMG_5495&op=modload&name=gallery&file=index&include=view_photo.php">

Thanks,

Grazer |

|

| Back to top |

|

|

Grazer

Joined: 16 Dec 2011

Posts: 183

City/Region: Yukon

State or Province: YT

C-Dory Year: 2004

C-Dory Model: 22 Cruiser

Vessel Name: C-Horse

Photos: Grazer

|

Posted: Fri Jan 31, 2014 11:16 pm Post subject: Posted: Fri Jan 31, 2014 11:16 pm Post subject: |

|

|

Sorry, Here's the photo of what I proposing to do.

|

|

| Back to top |

|

|

potter water

Joined: 12 Apr 2011

Posts: 1076

City/Region: Logan

State or Province: UT

C-Dory Year: 1997

C-Dory Model: R-21 Tug

Vessel Name: Poopsy

Photos: Still C-razy

|

Posted: Sat Feb 01, 2014 12:19 am Post subject: Posted: Sat Feb 01, 2014 12:19 am Post subject: |

|

|

Don't know for sure, but is top of the gunnels really cored? I wouldn't have thought so. But it would be good to know. It looks like you've already drilled it so did you find foam or wood core in the drill leavings?

_________________

You can tell a man his wife is ugly, but never ever criticize his dog, his gun, his truck or his boat.

Never let ignorance interfere with an opportunity to state a knowledgeable opinion

Testosterone Tales-Amazon.com

2006 C-Dory 22 Cruiser 2008-2014

1997 Ranger Tug 21 Classic 2016

KG7RC |

|

| Back to top |

|

|

AstoriaDave

Joined: 31 Oct 2005

Posts: 994

City/Region: Astoria

State or Province: OR

|

|

| Back to top |

|

|

Sunbeam

Joined: 23 Feb 2012

Posts: 3990

City/Region: Out 'n' About

State or Province: Other

C-Dory Year: 2002

C-Dory Model: 22 Cruiser

Photos: Sunbeam

|

Posted: Sat Feb 01, 2014 4:01 am Post subject: Posted: Sat Feb 01, 2014 4:01 am Post subject: |

|

|

| potter water wrote: | | Don't know for sure, but is top of the gunnels really cored? I wouldn't have thought so. But it would be good to know. |

The gunwales (flat top area) on my 22 are cored with balsa (as is most of the deck). There are some cut-away views of an older (1990's?) 22 that also show the coring. I'll upload one to my album and then come back and attach it here.

|

|

| Back to top |

|

|

williwaw

Joined: 05 Jan 2014

Posts: 148

City/Region: Portland

State or Province: OR

C-Dory Year: 2007

C-Dory Model: 23 Venture

Vessel Name: Williwaw

Photos: Williwaw

|

Posted: Sat Feb 01, 2014 11:23 am Post subject: Posted: Sat Feb 01, 2014 11:23 am Post subject: |

|

|

| I once had a drop of epoxy fall on my floor. After discovering it later I tried to pop it off but wound up taking the gel coat with it. So I would think you'll have no problems with adhesion if you just clean the surface. But know that whatever you attach will not come off again without a saw. If it were me, I'd probably go the 5200 route. |

|

| Back to top |

|

|

SEA3PO

Joined: 02 Nov 2003

Posts: 1835

City/Region: Chester

State or Province: CA

C-Dory Year: 2003

C-Dory Model: 22 Cruiser

Vessel Name: SEA3PO

Photos: SEA3PO

|

Posted: Sat Feb 01, 2014 12:28 pm Post subject: Posted: Sat Feb 01, 2014 12:28 pm Post subject: |

|

|

I had to remove something I had applied 5200 on, and was amazed at the strength of the bond.... I too would use 5200

I bought a tube of 5200 at Home Depot yesterday for $8.50

Joel

SEA3PO |

|

| Back to top |

|

|

Grazer

Joined: 16 Dec 2011

Posts: 183

City/Region: Yukon

State or Province: YT

C-Dory Year: 2004

C-Dory Model: 22 Cruiser

Vessel Name: C-Horse

Photos: Grazer

|

Posted: Sat Feb 01, 2014 3:43 pm Post subject: Posted: Sat Feb 01, 2014 3:43 pm Post subject: |

|

|

| Thanks for the responses. There is definitely balsa core in the deck of the gunnel. I am now rethinking my strategy of bonding the rodholder base to the gunnel, but rather gluing with 5200 since it can be removed at some point if needed. I will still set the screws in epoxy to seal the core and increase the strength of fastening. I would while the epoxy is curing, fasten the hardware with 5200. Is there any known issues with the two bonding agents (epoxy, and 5200) reacting negatively? |

|

| Back to top |

|

|

thataway

Joined: 02 Nov 2003

Posts: 21507

City/Region: Pensacola

State or Province: FL

C-Dory Year: 2007

C-Dory Model: 25 Cruiser

Vessel Name: thataway

Photos: Thataway

|

Posted: Sat Feb 01, 2014 4:40 pm Post subject: Posted: Sat Feb 01, 2014 4:40 pm Post subject: |

|

|

From the Scotty web site and your photo it appears as if you are going to mount this rod holder to the inside of the cockpit side deck, not the actual deck--as the outrigger mount is in the photo. The inside of the cockpit where you have your holes drilled should not be cored, although the deck part is.

Thru bolting should be very satisfactory--not screws. You don't need to route out core, and fill with epoxy if there is no core. 4000 or 4200 should be fine as a sealant. 5200 and epoxy is fine, just get rid of any amine surface blush. Use fender washers on the inside and this should be stronger than the wires of the rod holder.

_________________

Bob Austin

Thataway

Thataway (Ex Seaweed) 2007 25 C Dory May 2018 to Oct. 2021

Thisaway 2006 22' CDory November 2011 to May 2018

Caracal 18 140 Suzuki 2007 to present

Thataway TomCat 255 150 Suzukis June 2006 thru August 2011

C Pelican; 1992, 22 Cruiser, 2002 thru 2006

Frequent Sea; 2003 C D 25, 2007 thru 2009

KA6PKB

Home port: Pensacola FL |

|

| Back to top |

|

|

Grazer

Joined: 16 Dec 2011

Posts: 183

City/Region: Yukon

State or Province: YT

C-Dory Year: 2004

C-Dory Model: 22 Cruiser

Vessel Name: C-Horse

Photos: Grazer

|

Posted: Sat Feb 01, 2014 5:34 pm Post subject: Posted: Sat Feb 01, 2014 5:34 pm Post subject: |

|

|

| Just to clarify, the top three holes do not go through where there is backing but rather into the cored deck area like in Sunbeams photo. The bottom three holes have access to the back and therefore can be through bolted. I would like to wet out the cored holes allow it to soak in, apply a thickened epoxy to the screw threads and fasten the hardware in. If I put 5200 on the back of the rod holder base, both adhesives will be uncured at the time of securing to the boat. Will they cure properly? May never know as I don't plan on taking it off to find out. Hopefully someone else has done something like this before and can comment on it success or failure. |

|

| Back to top |

|

|

Sunbeam

Joined: 23 Feb 2012

Posts: 3990

City/Region: Out 'n' About

State or Province: Other

C-Dory Year: 2002

C-Dory Model: 22 Cruiser

Photos: Sunbeam

|

Posted: Sat Feb 01, 2014 6:27 pm Post subject: Posted: Sat Feb 01, 2014 6:27 pm Post subject: |

|

|

As a caveat, I'm not familiar with the piece of hardware you are installing. With that in mind, a few thoughts:

1) If you are through bolting (and I would be, with backing plates), then you may only need a bedding compound to... well.. bed (i.e. guard against water intrusion). In that case a super adhesive such as 5200 may not add much except a lot of angst if/when you ever need to remove the item (it breaks, you want to upgrade, you want to re-bed, etc.). If you do want or need some adhesion to hold the thing on, then perhaps consider 4200, which, like 5200 is a polyurethane, but with a bit less adhesion than 5200. I have removed things bedded in 5200, so it is possible, but it's not fun.

2) If you really are just wanting to bed, then you can consider other products with other properties. Polyurethane is good, and has a fair bit of adhesion, but the white can yellow with UV. Polyether (3M4000) is not supposed to yellow (I haven't been using it long enough to know for sure). I also don't know the numbers for its adhesive properties, but I would think it would probably come in around the same or maybe a bit less than 4200 (just a guess though). Butyl stays pliable for a long, long time, and is easy application and clean up, but is less adhesive. And so on.

3) Back to part of your original question: Asking about bonding to gelcoat. One thing I think about if I'm going to bond something to gelcoat is... what kind of strength does it need? Because gelcoat, while it is bonded to the fiberglass substrate, doesn't have a "really strong" bond to it. In other words, if you bonded something like a stud to a small area of gelcoat and then pounded on the stud, it would just break the gelcoat off of the substrate. I did some "experiments to destruction" comparing Weld Mount studs glued to gelcoat, to fiberglass substrate (after grinding off gelcoat), and a metal angle screwed into the core. The studs glued to the substrate (without gelcoat) were a lot harder to make fail than the ones just glued to gelcoat (they stuck to the gelcoat but the gelcoat broke off of the fiberglass substrate.

That's not to say I never bond anything to gelcoat; but it depends on what kind of force it's going to withstand, plus how much of the gelcoat surface area is involved (more is less likely to crack off than less).

Sunbeam |

|

| Back to top |

|

|

thataway

Joined: 02 Nov 2003

Posts: 21507

City/Region: Pensacola

State or Province: FL

C-Dory Year: 2007

C-Dory Model: 25 Cruiser

Vessel Name: thataway

Photos: Thataway

|

Posted: Sun Feb 02, 2014 11:12 am Post subject: Posted: Sun Feb 02, 2014 11:12 am Post subject: |

|

|

If you age going to put screws into the cored area--I would over drill, and under cut the fiberglass. You are not getting any strength from the screws into the core in any case, unless you are going to put a plug of epoxy, which is larger in the area behind the fiberglass than the hole. Just dipping the screws in epoxy, will not give them any more strength--the epoxy will come off the screw as you put it into the hole. Some people will use a machine screw, and tap the epoxy plug with a tap, instead of using screws.

If you want adhesion, the best is gong to be the 5200. But most likely you are not going to keep the boat forever, and someone in the future may want to remove this fitting.

My experience with 4000 is that it does not yellow in over 2 years sun exposure. The shear strength is close to 4200 the shear strength is much different in various materials.--but you can look it up in the 3 M spec sheets. |

|

| Back to top |

|

|

Grazer

Joined: 16 Dec 2011

Posts: 183

City/Region: Yukon

State or Province: YT

C-Dory Year: 2004

C-Dory Model: 22 Cruiser

Vessel Name: C-Horse

Photos: Grazer

|

Posted: Sun Feb 02, 2014 1:27 pm Post subject: Posted: Sun Feb 02, 2014 1:27 pm Post subject: |

|

|

Thanks Bob. I thought of that already and was hoping to get away from the backcut/epoxy plug technique. In reading West Systems manuals it refers to the epoxy plug as a technique to repair striped or oversized holes (as well as waterproofing the core). As for new holes, the basic technique for mounting hardware is described below with advanced mounting after (which is the technique I think you are describing but with an undercut behind the glass laminate).

Perhaps the advanced mounting method will work as you mention, but again I would want the back of the rod holder bracket to be sealed with a water proof flexible adhesive. If the epoxy plug cracks or the screw backs out there maybe room to allow moisture to access the core, hence the additional need for the sealant. The clamping pressure using the screws and machine bolts will hold it all together while things cure. |

|

| Back to top |

|

|

Sunbeam

Joined: 23 Feb 2012

Posts: 3990

City/Region: Out 'n' About

State or Province: Other

C-Dory Year: 2002

C-Dory Model: 22 Cruiser

Photos: Sunbeam

|

Posted: Sun Feb 02, 2014 2:46 pm Post subject: Posted: Sun Feb 02, 2014 2:46 pm Post subject: |

|

|

One thing to notice on the WEST System fastener bonding graphic is that the "just wet out the hole" screw method is shown on a door hinge, which is probably not going into thinnish fiberglass. They refer to wetting out the fibers, so it's not specific, but I imagine something like a door hinge being mounted to a thicker wooden door jamb. In that application you are taking a method that will already work fine (wood screws into deepish wood fibers) and just making it better.

Personally, I'm not a fan of screwing into fiberglass (i.e. with tapered screws). It just never seems that satisfying, and if you need to remove/replace (re-bed, send out for repair, etc.) it's getting worse each time you re-fasten with them. I like to overdrill, fill, and then tap for machine screws. That's not to say the method they illustrate with hinges won't work, but it wouldn't be my choice.

| Grazer wrote: | | ... but again I would want the back of the rod holder bracket to be sealed with a water proof flexible adhesive. If the epoxy plug cracks or the screw backs out there maybe room to allow moisture to access the core, hence the additional need for the sealant. The clamping pressure using the screws and machine bolts will hold it all together while things cure. |

If you get a chance, I would like to see what the hardware is you are attaching. Reason is I can't visualize what you are saying about wanting to seal the back of the bracket (do you mean the underside of the top? or the backing block? Reason I ask is that I don't like to seal backing blocks, myself).

Edited to add: Okay, I went to the link. Looks like it comes with its own "built in" backing block. I was thinking "well the side of the gunwale is not even cored," but I guess the upper three holes are going "sideways" into the deck core, aren't they. Those are ones I would want to overdrill/fill/tap. Will you have to make your own backing block (that is shorter, heightwise)?

I would slightly wonder how the lower fastener area would handle any force (flex) but you can probably get a good idea of that by giving it a "yank test." (I also don't really know how much force would go on this piece of hardware.

Thataway:

Good data on the polyether and UV, thanks. I've only had some in use for around 9 months and most of that time it has been out of the sun. |

|

| Back to top |

|

|

|

Search

Search Private Messages

Private Messages Profile

Profile Log in

Log in Register

Register Help

Help