| View previous topic :: View next topic |

| Author |

Message |

nordicstallion

Joined: 16 Dec 2007

Posts: 380

City/Region: Crescent City

State or Province: CA

C-Dory Year: 2004

C-Dory Model: 19 Angler

Vessel Name: Rylee Rose

Photos: Rylee Rose

|

Posted: Fri Aug 16, 2013 12:48 pm Post subject: Trailer lights Posted: Fri Aug 16, 2013 12:48 pm Post subject: Trailer lights |

|

|

| Trailer lights are making me nuts, granted I didn't have far to go! Decided to switch from incandesants to led. Thought that would solve constant problems. WRONG!! First I put in a new harness with butt connections. Results were poor as some worked and some didn't. Got a new harness & soldered everything. Same results. Decided ground connections not real good so I pulled all the grounds & ran a dedicated ground wire connecting all the lights to the plug at the truck taking the trailer out of the loop. Tail & brake have always worked good. The marker lights,not. First all worked then one fender light went very dim. Then it worked good & another on the other fender went dim & one marker on the trailer toung went out. Next time out both lights on the toung worked. Then the one on the fender started working,& the one on the front of the same fender went dim & the same one on the tong went out again. I can always see a very faint light from the offending lights. Suspect it's some sort of incompatibility with my 2005 toyota tundra incandesant system. Where am I going wrong or is it just caused by stray signals coming in from the Oort Cloud & there's nothing I can do about it other than prayer? |

|

| Back to top |

|

|

potter water

Joined: 12 Apr 2011

Posts: 1076

City/Region: Logan

State or Province: UT

C-Dory Year: 1997

C-Dory Model: R-21 Tug

Vessel Name: Poopsy

Photos: Still C-razy

|

Posted: Fri Aug 16, 2013 1:48 pm Post subject: Posted: Fri Aug 16, 2013 1:48 pm Post subject: |

|

|

It is always grounds. Now, finding the bad ground(s) is the big problem. Do the LED's get their ground from the frame at each light or do they have a black wire that goes to a main ground wire? If you are running ground or power wires in a "chain" fashion you can create all kind of trouble. You need to start with the connector that is on the trailer tongue. Make sure that your grounds from all lights are wired to ONE spot on the trailer frame and that same spot has a nice fat wire coming from the connector at the tongue. Grounding rule number one: Don't rely on the frame for conducting grounds. If everything is nicely grounded, then hook up the wire from the tongue connector to the running lights. Verify they are all nice and bright. Then add in the parking, turn and brake lights one at a time. If the grounds are as I've suggested, the whole issue of dim and bright intermittent will NOT be the grounds, but will be bad connectors/solder joints on the power side of the maker or tail lights. Your Toyota supply doesn't care about incandescent or LED. 12 volts is 12 volts. Incandescent or LED.

The other thing to think about is that the LED's are mass assembled in a Chinese factory and have a high new part defect statistic. (By personal experience) They often have problems in the mini circuit boards that most come with. LED's are not a panacea for light problems. But when you get good LED parts they are nice. But are still subject to water damage, heat and cold and corrosion. I'm sticking with my tried and true incandescent for the trailer. They are cheap and available anywhere. On the boat, LED's are the way to go for sure because of limited battery power when not running the engines.

In short and to repeat, get the grounds all together by wire, not by frame. Then the rest should go well.

_________________

You can tell a man his wife is ugly, but never ever criticize his dog, his gun, his truck or his boat.

Never let ignorance interfere with an opportunity to state a knowledgeable opinion

Testosterone Tales-Amazon.com

2006 C-Dory 22 Cruiser 2008-2014

1997 Ranger Tug 21 Classic 2016

KG7RC |

|

| Back to top |

|

|

nordicstallion

Joined: 16 Dec 2007

Posts: 380

City/Region: Crescent City

State or Province: CA

C-Dory Year: 2004

C-Dory Model: 19 Angler

Vessel Name: Rylee Rose

Photos: Rylee Rose

|

Posted: Fri Aug 16, 2013 2:32 pm Post subject: Posted: Fri Aug 16, 2013 2:32 pm Post subject: |

|

|

| You would think that if a light were bad it would stay bad but they seem to be taking turns. For a ground I used 10 guage & the only place the wire was cut was where one joins the other at the wishbone on the tongue. The trailer isn't being used as part of the grounding system. The ground wire goes straight to the four prong plug. The problem is confined to the marker lights only, of whitch there 6. 2 on each fender & 1 on either side of the tongue at the wishbone. |

|

| Back to top |

|

|

Jack in Alaska

Joined: 17 Aug 2004

Posts: 1191

City/Region: Anchorage/Ninilchik

State or Province: AK

C-Dory Year: 2005

C-Dory Model: 26 Pro Angler

Vessel Name: HIGH TIDE II

Photos: HIGH TIDE II

|

Posted: Fri Aug 16, 2013 6:14 pm Post subject: Posted: Fri Aug 16, 2013 6:14 pm Post subject: |

|

|

Vern..........

I am sorry to hear of your trailer light troubles. That same thing made me nuts...made me nuts..made me nuts several weeks ago. My lights all worked perfectly one day and the next I had a mess as you did. But why? I went for the grounds. All ok but I loosened them , cleaned them, re-tightened them and checked for continuity with a Simpson.

Still no lights. Cut each light power wire and used a power source from a batt. charger. All lights were bright and clear. Reconnected each power wire. Still no lights from the truck (not a rice rocket but a genuine amellican made ram). Truck made no difference. Checked each output from the truck and the ground. All ok. No lights still. Making me nuts again just remembering all this.

I had a new harness but only 25' long. Trailer 27' long.

So I cut the 1st 4' of the new harness and planned to splice it to my trailer. Up by the tongue was a black wire covering with all of the trailer wires in it. I took it loose, slid the covering back and WHOOHAAA there it was. The trailer manuf. had already spliced on the last 4' but the splices had corroded and several had broken off. I cleaned up the trailer ends and re-spliced my new harness onto it. Used crimps but packed them each full of silicone dielectric grease. Plugged lights in and...all lights work and still are working today after 6 dunks in the salt water.

It was NOT the ground in this case but 99% of the time it is. Makes me nuts......nuts.....nuts.

I have no useful suggestions but I do wish you luck in the search for lights. Let us know what you find.

_________________

On the HIGH TIDE-II, wife Carolyn and I.....Another summer fishing on the HIGH TIDE II in the Cook Inlet at Cape Ninilchik, Alaska.

HIGH TIDE-II; 2005 26' ProAngler; 2003 200 Honda / 2009 9.9 Honda high thrust

No. CD026021I405; AK-5008-AK

MSSI No. 338143486(cancelled)

HIGH TIDE; 1983 Angler Classic 22'; 90 Honda/ 9.9 Tohatsu-sold 2009 to son Dan (flatfishfool)

Stolen & stripped in Aug. 18

Bare hull & trailer sold in Nov. |

|

| Back to top |

|

|

akc-dory

Joined: 09 Jul 2011

Posts: 27

City/Region: Fairbanks

State or Province: AK

C-Dory Year: 1993

C-Dory Model: 16 Angler

|

Posted: Sat Aug 17, 2013 2:47 am Post subject: Posted: Sat Aug 17, 2013 2:47 am Post subject: |

|

|

| I try to use crimp terminals and butt connecters that are made with shrink tubing on my trucks and trailer. So after you crimp you add flame as with any regular shrink tubing and you end up with a much more weatherproof terminal or connection . More expensive at about 50 cents each, but much less corrosion . |

|

| Back to top |

|

|

thataway

Joined: 02 Nov 2003

Posts: 21387

City/Region: Pensacola

State or Province: FL

C-Dory Year: 2007

C-Dory Model: 25 Cruiser

Vessel Name: thataway

Photos: Thataway

|

Posted: Sat Aug 17, 2013 11:07 am Post subject: Posted: Sat Aug 17, 2013 11:07 am Post subject: |

|

|

There are several points here: Some trailer manufactures add the plug and harness to the truck after the trailer is wired, and used plain but connectors. This could be that the company had a choice of plug types: 7 round, 6 round, 5 flat or 4 flat. Many trailer companies have a molded in 4 or 5 flat, and then no but connectors in the wiring. (But there are going to be splices to the yellow running lights on the sides of the tongue A frame, the fenders, and the tail lights to one side. The brake and turn are a continuous wire from the molded plug to the R and L tail lights.

Then there is how to treat the butt or "Y" connectors. The packing with silicone dielectric grease is one way, but if you put on heat shrink tubing, it is less likely to adhere to the wire because of the silicone. There is another philosophy--and that is to make the connection with a NO OX coating on the ends of the wire--and then cover the entire connection with adhesive shrink wrap tubing--and heat shrink it. I have heard it argued that the NO OX may make the crimp less effective. I suspect that aka-dory is using the butt connectors with adhesive lined heat shrink tubing (which is better than no adhesive lined). Then there are those who use liquid tape over the entire butt connector.

When re-wiring, it is best to use a set which has the molded in 5 pin flat connector (assuming that you have surge brakes and selenoid lock out), rather than splicing in a new 5 pin connector.

There is also the problem that many of the "sets" of trailer wiring one buys is not marine grade wire--not tinned, and often of a lower gauge than it should be. If I have to rewire a trailer from scratch, I would go ahead and buy marine grade tinned wire, at least 14 gauge, and use adhesive heat shrink butt connectors. The "Y"--for the amber running lights is a whole other issue. The 3 way connectors are not water proof. There are several ways to handle this. One is strip back insulation, keep the wire intact to wrap and solder, then coat with liquid tape, and tightly cover with quality vinyl tape --and then secure this to the trailer frame. Another route is to cut the main tail light wire at each 'Y", use a reducing butt connector--that is so you can accommodate the different size bundle of wire-if wrapping two #14 wires together--it will be closer to a #12, and too big for a #14 crimp--so use a 12 to 14 butt reducing butt connector, and then cover this entire splice with adhesive shrink wrap tubing. However often these small running lights are only #16 or #18 wire, and you can get away with using a #14-16 connector with both wires in the crimp.

_________________

Bob Austin

Thataway

Thataway (Ex Seaweed) 2007 25 C Dory May 2018 to Oct. 2021

Thisaway 2006 22' CDory November 2011 to May 2018

Caracal 18 140 Suzuki 2007 to present

Thataway TomCat 255 150 Suzukis June 2006 thru August 2011

C Pelican; 1992, 22 Cruiser, 2002 thru 2006

Frequent Sea; 2003 C D 25, 2007 thru 2009

KA6PKB

Home port: Pensacola FL |

|

| Back to top |

|

|

Sea Wolf

Joined: 01 Nov 2003

Posts: 8650

City/Region: Redding

State or Province: CA

C-Dory Year: 1987

C-Dory Model: 22 Cruiser

Vessel Name: Sea Wolf

Photos: Sea Wolf

|

Posted: Sat Aug 17, 2013 1:35 pm Post subject: Posted: Sat Aug 17, 2013 1:35 pm Post subject: |

|

|

Here's a post I made about six years back (2007) about these issues:

Dang, the eternal stop/ tail-light deliemma!

Sometimes it seems nothing works! (at least for very long).

Here are some things to think about that can help your system work, although just as sure as I, or anyone, makes a specific recommendation, someone else will find that the named approach didn't work for them!

Grounds- One of the biggest problems with trailer lights is poor grounding. It's just as important to the circuit as the hot wire. Most trailers are wired so that the frame is grounded, and all lights depend on a good ground to the frame to work. Problem is that the ground wire from the light to the frame as well as the main ground wire up front where the harness is first grounded can corrode and break up the circuit.

First thing here is to

1) solder wires as good as possible, using

liquid electrical tape to cover the joint, or

2) use quality solderless connenectors with shrink plastic sealant tubing included or placed over them, or

3) some combination of the above that you prefer to keep the water/salt away from the metal wires and fittings.

I actually "double ground" everything: all grounds are made to the frame as normal, PLUS I ground every light back to the front harness with wires. In this way, the filament can find ground back through the frame OR the ground wire. Yes, it's a lot of extra trouble to run a second return circuit, but weak, intermittent grounds through the trailer frame (especially a bolted, not welded one, are a real problem.

Weak grounds can result in the light filaments grounding back through the lamp base and then through another filament and the subsequent wiring to find ground, which then lights up the other filament and produces a nonsense light pattern that seems to defy analysis.

If the double grounds seem redundant, that's good, because redundancy is one way to fight circuit loss, which is a easy victum to any interruption when no alternate paths are available in a series circuit.

Another trick in this area, is to cross-link the tail light filaments from right, left and center fixtures as well as bring two hot wires back from the front harness tail light source to the rear of the trailer. Lose one wire, and the lights still work.

Ok, so I'm paranoid about open circuits, but my lights generally do stay on.

When we raced small sailboats, we made a "light bar" that fit across the stern/transom of the boat and contained the lights as well as held the mast when trailering. A similar light bar on a C-Dory would allow the removal of the light system before launching to entirely eliminate the submersion issue.

LED's will undoubtably be the way to go, sooner or later. The first class truck-style components originally cost about $65 each, but less expensive alternatives in the $30 range are appearing. I don't know whether their quality is up to par, though.

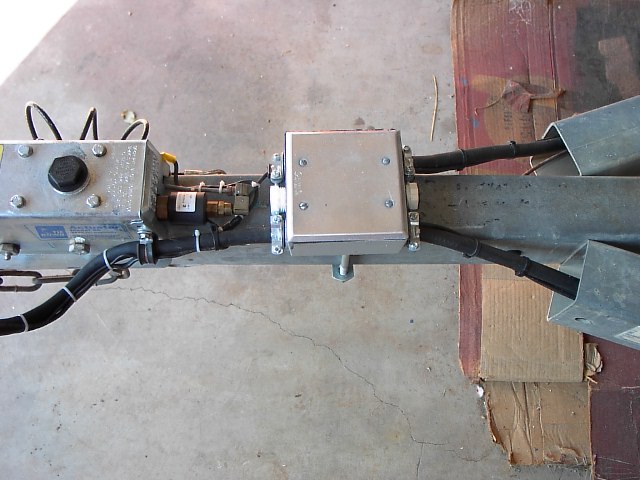

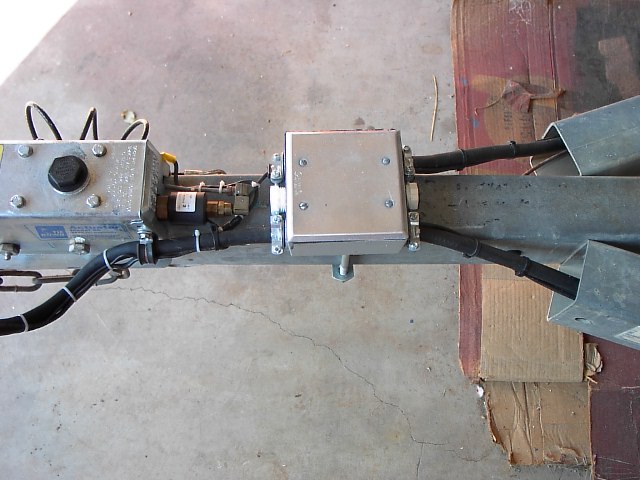

Another way to eliminate common problems is to build a junction box up on the front of the trailer tongue to organize and make more solid the junctions between the incoming light harness from the tow vehicle and the outgoing lines to the trailer marker lights and stop/tail lights.

The stop/turn signal lights usually only have one junction to make, but the tail light incoming wire can be split into several wires for the marker lights and various tail lights, and that connection can be a funny one without some forethought. So can a ground junction in the "double ground" system. To solve this problem, I like to crimp ring connectors on each wire to be connected, bolt them together with a machine screw and nut, and then coat the entire connection with liquid electrical tape, and then tape wrap it. Enclosed in a sealed metal box, this connection seems bulletproof.

Using heavy, well insulated wires for the run back to the lights is also a plus.

I used 10 gague, 3-conductor heavy duty black rubber covered extension cord wire on my last re-wire. You have to figure out a way to keep from trapping water in the space between the wires and the cover, but the cover eliminates wire chafe and the resultant shorts. The cheap, flat 4-conductor wire usually supplied with new trailers is a ready made problem for chafe in the world of sharp-cornered trailer tubing and channel.

In another vein, WestBar, I believe, makes the sealed clear plastic bubble units that have three bulbs inside that really avoids the corroded bulb base/socket issues. These replaceable units fit in the special made red lens and base fittings made for them. I use only these or LED's.

No end to this subject! Nor no absolute bulletproof system!

But, just like the mousetrap, everyones trying to get a better one invented!

Joe.

JUNCTION BOX FOR PROTECTING CONNECTIONS. NOTE WIRING SIZE AND COVERING/INSULATION.

Source: http://www.c-brats.com/posting.php?mode=quote&p=7895y

_________________

Sea Wolf, C-Brat #31

Lake Shasta, California

"Most of my money I spent on boats and women. The rest I squandered'. " -Annonymous |

|

| Back to top |

|

|

Jack in Alaska

Joined: 17 Aug 2004

Posts: 1191

City/Region: Anchorage/Ninilchik

State or Province: AK

C-Dory Year: 2005

C-Dory Model: 26 Pro Angler

Vessel Name: HIGH TIDE II

Photos: HIGH TIDE II

|

Posted: Sat Aug 17, 2013 3:14 pm Post subject: Silicone Dielecric compound Posted: Sat Aug 17, 2013 3:14 pm Post subject: Silicone Dielecric compound |

|

|

I use the silicone dielectric compound in my butt connections because we used it in the oilfield in downhole electrical connections subjected to 5000 psi, 250F and corrosive fluids. Works great.

A partially full 1 lb. jar of it followed me home 16 yrs ago when I retired. After all of the uses it is still 3/4 full so I will have plenty until the end.

Shrinkable crimp connections work but are a giant PITA to use in cramped conditions. Trying to wrap with shrinkable tape (also oilfield used) or electrical tape is difficult to do it properly.

Trailer lights are just a plain difficult situation. Electrical and salt water are not friends. |

|

| Back to top |

|

|

nordicstallion

Joined: 16 Dec 2007

Posts: 380

City/Region: Crescent City

State or Province: CA

C-Dory Year: 2004

C-Dory Model: 19 Angler

Vessel Name: Rylee Rose

Photos: Rylee Rose

|

Posted: Sat Aug 17, 2013 8:26 pm Post subject: Posted: Sat Aug 17, 2013 8:26 pm Post subject: |

|

|

| Hi kids! That salt water is a love/hate thing! Salt water has been berry, berry good to me but it certainly has a nasty, vicious, unforgiving nature for an old flatlander like myself. It's truly wonderful retiring to the north coast but my ass crack is even starting to rust. I can't complain ......but I do! Vern |

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You cannot download files in this forum

|

|

Search

Search Private Messages

Private Messages Profile

Profile Log in

Log in Register

Register Help

Help