| View previous topic :: View next topic |

| Author |

Message |

thataway

Joined: 02 Nov 2003

Posts: 20815

City/Region: Pensacola

State or Province: FL

C-Dory Year: 2007

C-Dory Model: 25 Cruiser

Vessel Name: thataway

Photos: Thataway

|

Posted: Sat Sep 13, 2008 4:01 pm Post subject: Posted: Sat Sep 13, 2008 4:01 pm Post subject: |

|

|

There are several photo's in the "Thataway" album on under cutting:

This is a Dremel tool drum sander--the piece is of a boat I cut up for survey purposes and is balsa cored deck. I have cut the deck on the edge for demonistration purposes. You can use a smaller "tool" for the under cutting if there is a smaller hole. But if there is an area with wet core, you may want to remove this wet core.

_________________

Bob Austin

Thataway

Thataway (Ex Seaweed) 2007 25 C Dory May 2018 to Oct. 2021

Thisaway 2006 22' CDory November 2011 to May 2018

Caracal 18 140 Suzuki 2007 to present

Thataway TomCat 255 150 Suzukis June 2006 thru August 2011

C Pelican; 1992, 22 Cruiser, 2002 thru 2006

Frequent Sea; 2003 C D 25, 2007 thru 2009

KA6PKB

Home port: Pensacola FL |

|

| Back to top |

|

|

eNORMous

Joined: 08 Jul 2008

Posts: 348

City/Region: Beaufort

State or Province: NC

C-Dory Year: 2007

C-Dory Model: 25 Cruiser

Vessel Name: Antibody

Photos: Antibody

|

Posted: Sat Sep 13, 2008 5:28 pm Post subject: Posted: Sat Sep 13, 2008 5:28 pm Post subject: |

|

|

Jack wrote"

"To my pleasant surprise I found good solid new looking wood in the transom in all of the holes. As my boat is 25 yrs. old that has been working on my mind. No more. Some of those old holes only had RTV in them."

That is great news to hear!!! GOOD DEAL! I hope you find the same 25 years from now!

Norm

_________________

I am what I am & that's all that I am & there ain't no more.

E Pluribus Normus

PLB Beacon ID: 2DCE5DE29CFFBFF |

|

| Back to top |

|

|

Chica

Joined: 05 Nov 2003

Posts: 57

City/Region: Butte

State or Province: MT

C-Dory Year: 2004

C-Dory Model: 22 Angler

Vessel Name: Chica

|

Posted: Sun Sep 14, 2008 10:14 am Post subject: Repairing small holes in hull Posted: Sun Sep 14, 2008 10:14 am Post subject: Repairing small holes in hull |

|

|

Which epoxy are you using to fill the drilled out, undercut holes? The marine -tex I have is not suitable for use in a syringe and some epoxies have a warning in the small print,"Not for prolonged immersion in water" ie, loctite's extra time epoxy. I like the idea of filling with a syringe and needle and filling as you withdraw the needle.A name please.

Chica |

|

| Back to top |

|

|

westward

Joined: 18 Feb 2005

Posts: 718

City/Region: Seattle

State or Province: WA

C-Dory Year: 1985

C-Dory Model: 16 Angler

Vessel Name: TBD

Photos: Steady Eddy

|

Posted: Sun Sep 14, 2008 1:05 pm Post subject: Posted: Sun Sep 14, 2008 1:05 pm Post subject: |

|

|

| Haven't read this entire thread so apologies if this has already been mentioned: Epoxy is great below the waterline or otherwise hidden from view where waterproofing/sealing trumps appearance. Higher up, especially in highly visible areas, you might have the following challenge: Chemicals in epoxy, even after curing, will "suck" the hardeners out of the gelcoat placed over the epoxy as a final finish, leaving the gelcoat patch uncured and gummy. The gummy spots can't be sanded and collect dirt, fingerprints, etc. I've run into this more than once. So what I'm saying is: If you will finish the repair with gelcoat it might be better to use fiberglass resin as your substrate repair material. I believe polyurethane paints, and certainly epoxy paints, are compatible with an epoxy substrate. Also, make sure you wear rubber gloves when working with epoxy and otherwise avoid touching it and minimize breathing its vapors or you could become sensitized and unable to be around it. Mike. |

|

| Back to top |

|

|

thataway

Joined: 02 Nov 2003

Posts: 20815

City/Region: Pensacola

State or Province: FL

C-Dory Year: 2007

C-Dory Model: 25 Cruiser

Vessel Name: thataway

Photos: Thataway

|

Posted: Sun Sep 14, 2008 5:02 pm Post subject: Posted: Sun Sep 14, 2008 5:02 pm Post subject: |

|

|

I certainly agree with Westward about skin protection--and what degree of respiratory safeguards are available. However this ""suck" the hardeners out of the gelcoat placed over the epoxy" is a bit of a misnomer--see below for explaination of the role of improperly cured epoxy and gel coat hardening.

The epoxy has far better adherence than polyester materials; they are also far more resistant to intrusion of water. At one point I was also pesimestic about use of gel coat over epoxy. Proset (West Systems professional products, has done a large amount of testing on this subject). I rebuilt an 18 foot Century CC which fell 30 + feet in a dry stack blow down, using epoxy for the structural repair, and Spectrum gelcoat for the finish. 3 years later you cannot tell where the repairs were made and where gelcoat was put over gel coat/polyester or over epoxy.

The adherance of gel coat to epoxy is at times a problem, but there are techniques which will minimize this.

West systems adresses these issues at: http://www.westsystem.com/ewmag/22/polyester.html

Another relitatively short answer I copied from West Systems is as follows:

There is a common misconception, fueled by some gelcoat manufacturers and by some expensive failures in the field, that gelcoat will not bond to epoxy. Polyester resin bonds poorly in a secondary (mechanical) bonding situation which consequently makes epoxy the resin of choice for repairs. How can one be squared with the other?

The answer is surprisingly simple - gelcoat does bond to a properly cured and prepared epoxy surface. There are a couple issues to be aware of to have success making this repair. There are three situations that cause gelcoat to not cure over epoxy... all related to the hardener chemistry. Epoxy hardeners are basically a blend of amines, which can terminate the chain reaction of the radical molecule that is the basis of polyester (and vinylester) cure chemistry. So by carefully mixing, curing, and preparing of the epoxy so that there are no unreacted amines to interfere with the gelcoat cure, gelcoat bonds quite well to epoxy.

The first situation is undercured epoxy. Gelcoat applied to undercured epoxy will be in contact with unreacted amines and the cure will be halted.

The second situation is if the epoxy is mixed off ratio so that it is hardener rich, again leaving unreacted amines free to interfere.

Third is the issue of amine blush, commonly called blush. Blush is a surface phenomena that is a reaction of the amine molecules at the surface with the carbon dioxide in the air. It forms easiest in the presence of moisture, so working in cool, humid environments will maximize the formation of blush. Any amine hardener has the potential to blush, but it can be minimized by careful choices of amines in the formulation. In fact, WEST SYSTEM 207 Special coating hardener is one of the lowest blushing hardeners on the market and still maintains structural properties on par with our other hardeners. Regardless of chemistry, blush is very easily dealt with because it is water soluble. A simple wash with clear water removes the blush. No soap, no solvents. Then sand that washed surface with 80 grit paper to provide the gelcoat with sufficient key so it won't run. Be sure to use non-air inhibited gelcoat that has a paraffin wax added. Gelcoat is applied over epoxy on a routine basis everyday in boatyards that are aware of these issues.

There are also gel coats which are specifically formulated to adhere with epoxies. Vinylester resins adhere better than polyester, and at times vinylester is used as a tie coat. Also tie coats for epoxy gel coat interface have been developed by :Neste, CCP, Duratec, intraplastic, Ferro, Scott Bader and others. There are any number of epoxy laminated boats which have a gel coated surface--however, I personally prefer 2 part LP painting of an epoxy composite.

As to applying epoxy to holes or under cut areas. You do not want to use un-thickened epoxy, such as in the two part tubes. You want to mix the epoxy with cabosil (fumed silica) as a thickener and a filler agent, such as medium density filler (depending on the application). I usually use a peanut butter thickness, and apply with a very thin spatchula, or a sliver of wood/tooth pick for application and packing down into the hole. The epoxy is left proud of the surface and then cleaned with water and sanded to make a surface for the gel coat. If you want to inject an epoxy, then buy the tubes which are available for caulking guns and then inject the thickened epoxy thru drilled holes.... |

|

| Back to top |

|

|

Adeline

Joined: 03 Nov 2003

Posts: 985

City/Region: Vancouver

State or Province: WA

C-Dory Year: 1989

C-Dory Model: 22 Cruiser

Vessel Name: Adeline

Photos: Adeline

|

Posted: Sun Sep 14, 2008 7:54 pm Post subject: Posted: Sun Sep 14, 2008 7:54 pm Post subject: |

|

|

Another method that has worked well for me.

_________________

Pete

|

|

| Back to top |

|

|

mailbox101

Joined: 31 Mar 2008

Posts: 227

City/Region: Pacifica

State or Province: CA

C-Dory Year: 2008

C-Dory Model: 26 Venture

Vessel Name: Blue Eagle

Photos: Blue-Eagle

|

Posted: Mon Sep 15, 2008 4:23 am Post subject: Posted: Mon Sep 15, 2008 4:23 am Post subject: |

|

|

| If you are going to change your mind and use a piece of Starboard couldn't you just match the holes on the Starboard to the holes you already drilled in the boat? Then you wouldn't need to patch anything. |

|

| Back to top |

|

|

Adeline

Joined: 03 Nov 2003

Posts: 985

City/Region: Vancouver

State or Province: WA

C-Dory Year: 1989

C-Dory Model: 22 Cruiser

Vessel Name: Adeline

Photos: Adeline

|

Posted: Mon Sep 15, 2008 8:36 pm Post subject: Posted: Mon Sep 15, 2008 8:36 pm Post subject: |

|

|

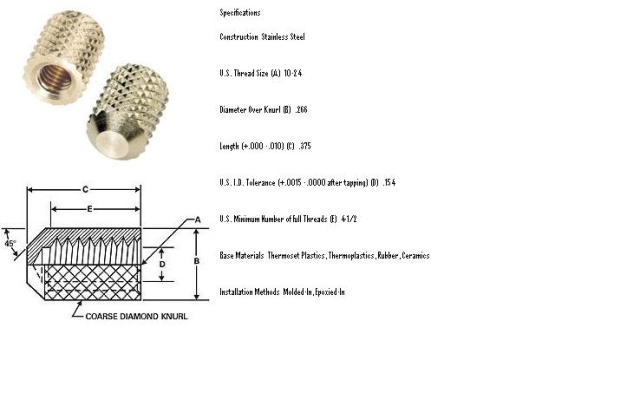

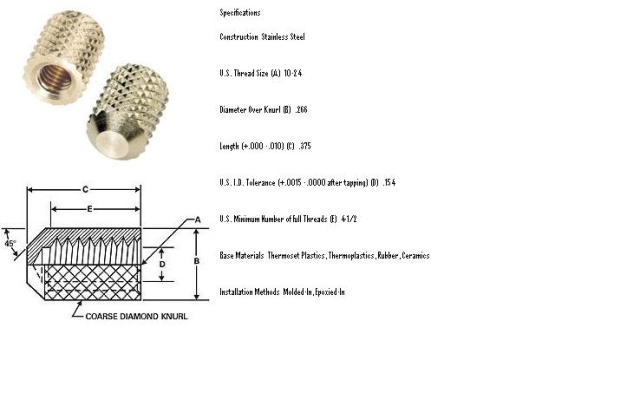

| Quote: | | couldn't you just match the holes on the Starboard to the holes you already drilled in the boat? |

From the photos it's difficult to appreciate the size difference between the old Lowrance Bracket and the new Airmar Bracket. As I recall, I was uncomfortable with securing such a large plate (btw- it's polyethylene) using the tight hole pattern from the Lowrance Bracket. Leverage issues. As things turned out I could've (should've ?) gone that way. You see, I went back later and drilled out the capsules and epoxied in threaded inserts . I'd become concerned that a flotsam strike (on the transducer) might crack the epoxy. It's real strong but somewhat brittle.  |

|

| Back to top |

|

|

thataway

Joined: 02 Nov 2003

Posts: 20815

City/Region: Pensacola

State or Province: FL

C-Dory Year: 2007

C-Dory Model: 25 Cruiser

Vessel Name: thataway

Photos: Thataway

|

Posted: Mon Sep 15, 2008 9:49 pm Post subject: Posted: Mon Sep 15, 2008 9:49 pm Post subject: |

|

|

If one uses mill fibers in the epoxy it is quite strong. I never advocate using plain epoxy resin for any filling application. There are boats which have deck fittings which are mounted with bolts into tapped, re-inforced epoxy.

The reason to use a polyethylene block is that allows one one drill holes to one's content and re-position/change out transducers. Often the bracket height has to be changed--and using the Starboard allows this to be done almost at will. |

|

| Back to top |

|

|

Adeline

Joined: 03 Nov 2003

Posts: 985

City/Region: Vancouver

State or Province: WA

C-Dory Year: 1989

C-Dory Model: 22 Cruiser

Vessel Name: Adeline

Photos: Adeline

|

Posted: Mon Sep 15, 2008 10:07 pm Post subject: Posted: Mon Sep 15, 2008 10:07 pm Post subject: |

|

|

| Quote: | If one uses mill fibers in the epoxy it is quite strong. I never advocate using plain epoxy resin for any filling application. There are boats which have deck fittings which are mounted with bolts into tapped, re-inforced epoxy.

The reason to use a polyethylene block is that allows one one drill holes to one's content and re-position/change out transducers. Often the bracket height has to be changed--and using the Starboard allows this to be done almost at will. |

I agree 100%

If I was starting over new I'd install the biggest poly plate that would fit. Just in case I wanted to reposition/replace or install a second transducer. I'd secure it to stainless steel threaded inserts bedded in epoxy/milled fibers. |

|

| Back to top |

|

|

breausaw

Joined: 18 Jan 2006

Posts: 1222

City/Region: Anchorage

State or Province: AK

C-Dory Year: 2007

C-Dory Model: 25 Cruiser

Vessel Name: Triple J

Photos: Triple J

|

Posted: Tue Sep 16, 2008 4:34 pm Post subject: Posted: Tue Sep 16, 2008 4:34 pm Post subject: |

|

|

As mentioned when I started this thread I considered using G/flex. I have since went ahead and tried it on a couple of applications, one filling holes left from a removed transducer, and the other filling and repairing a horizontal canvas snap that had worked itself lose.

In both instanced the product seemed to work well and the syringe applicators that come with the produce worked great for back filling the transducer holes; had to tape over the transducer holes to keep the epoxy from running out. I also over drilled the holes some to clean them out.

When I eventually upgrade my sonar it will be with an in-hull transducer, no more holes drilling in the transom; unless I opt for trim tabs.

_________________

Jay

2007 22ft C-Dory Triple J 2007-2012

2007 25ft C-Dory Triple J 2012-2018

Boatless for now but looking |

|

| Back to top |

|

|

thataway

Joined: 02 Nov 2003

Posts: 20815

City/Region: Pensacola

State or Province: FL

C-Dory Year: 2007

C-Dory Model: 25 Cruiser

Vessel Name: thataway

Photos: Thataway

|

Posted: Tue Sep 16, 2008 11:21 pm Post subject: Posted: Tue Sep 16, 2008 11:21 pm Post subject: |

|

|

Jay,

Where are you going to put the "in hull" transducer? To my knowlege the entire bottom hull of the C Dory 22 is cored (the only exception may be the small area just in front of the drain plug, where the bilge pump is located--and this may be solid???.

A depth finder (ultrasonic) transducer will not shoot thru a cored hull. The balsa core interface will stop the beam. If you want to shoot thru a cored hull, you have to remove the core. Then under cut the edges of the balsa core, finally glass over the bottom (since is is no longer as thick or strong)--and then install the transducer in this area with no core--using either mineral oil, epoxy or silicone sealant.

The other option is to cut a hole in the hull with a hole saw. In that case it is essential to undercut the core, and fill it for at least half an inch (to avoid crushing the core as you tighten the nut on the thru hull transducer. (This is a thru hull installation). Both of these are far greater challanges than the filling of transom holes and using a poly block. |

|

| Back to top |

|

|

breausaw

Joined: 18 Jan 2006

Posts: 1222

City/Region: Anchorage

State or Province: AK

C-Dory Year: 2007

C-Dory Model: 25 Cruiser

Vessel Name: Triple J

Photos: Triple J

|

Posted: Wed Sep 17, 2008 6:07 pm Post subject: Posted: Wed Sep 17, 2008 6:07 pm Post subject: |

|

|

| thataway wrote: | Jay,

Where are you going to put the "in hull" transducer? To my knowlege the entire bottom hull of the C Dory 22 is cored (the only exception may be the small area just in front of the drain plug, where the bilge pump is located--and this may be solid???. |

Bob

From what I understand this area is solid, and thereís plenty of room for an in-hull transducer; could be wrong but thatís the plan.

Now this isnít going to happen anytime soon, but if I can get a good deal on a 1KW RMS sonar off e-Bay it may happen sooner. Not that Iím totally dissatisfied with my current Garmin 250C with its 400 watts RMS, but it just donít cut the mustard in deep water.

So your probable wondering why in the world do I need accurate returns from that far down? Well, the shrimp we go after up here hang out from 400 to 800 feet, and Iíve had fantastic luck in 600 to 700 feet. Now most the time I can get an accurate return from 650 to about 700 feet, on a good day. When you set on the shrimp its usually desirable to drop your pots up hill on a steep slope, if you miss the mark by as little as 100 feet you could be dropping your first pot into to abyss-no kidding. When you see pot buoys floating by in 1300 to 1500 feet you know someone missed the mark. |

|

| Back to top |

|

|

siddfynch

Joined: 14 Jul 2008

Posts: 39

City/Region: Anchorage

State or Province: AK

C-Dory Year: 1983

C-Dory Model: 22 Classic

Vessel Name: XerxSeas

Photos: Xerxseas

|

Posted: Sat Oct 04, 2008 4:28 pm Post subject: Great thread Posted: Sat Oct 04, 2008 4:28 pm Post subject: Great thread |

|

|

In rummaging thru my garage, I found a bunch of System 3 epoxy and hardener that came with a kayak kit. Any reason I can't use this stuff instead of the West system epoxy that everyone is recommending here?

I'd be using it to fill the holes below waterline that were drilled by the previous owners for a couple of transducers and trim tabs. Also for whatever new holes I drill to place Starboard (HDPE) onto the spot for teh new transducer and other such toys.

So back to the question: Is System 3 an acceptable alternative to West for epoxy use below waterline? |

|

| Back to top |

|

|

thataway

Joined: 02 Nov 2003

Posts: 20815

City/Region: Pensacola

State or Province: FL

C-Dory Year: 2007

C-Dory Model: 25 Cruiser

Vessel Name: thataway

Photos: Thataway

|

Posted: Sat Oct 04, 2008 9:58 pm Post subject: Posted: Sat Oct 04, 2008 9:58 pm Post subject: |

|

|

System three is an excellent epoxy. (Actually few of the retailers actually formulate the epoxy--they buy it from large chemical companies--when we were building boats we got epoxy in large containers which had "Shell Chemical" on the outside.)

For some reason System Three seems to have caught on more with the kayak builders. As long as the proper ratios are used, it will work fine. |

|

| Back to top |

|

|

|

Search

Search Private Messages

Private Messages Profile

Profile Log in

Log in Register

Register Help

Help