| View previous topic :: View next topic |

| Author |

Message |

bmcminn

Joined: 20 Jul 2019

Posts: 65

City/Region: Bellingham

State or Province: WA

C-Dory Year: 1992

C-Dory Model: 19 Angler

Vessel Name: Polū

Photos: bmcminn

|

Posted: Sat Nov 23, 2019 11:42 pm Post subject: Posted: Sat Nov 23, 2019 11:42 pm Post subject: |

|

|

My plan this week had been to reseal the lazaret hatches then see if I just needed to replace them, stbd in particular has been leaky. But after learning a little about this core stuff and reading a post Bob wrote about hatches I realized there might be a bigger issue. Sure enough, it's soggy wood around this side and I'm sure the other too. I'm hoping that with these I can simply dig out to 'dry enough' and then fill with expanding foam, then epoxy. There is a small leak on the bow hatch and I had thought I'd pull it and reseal also, now I'm wondering if it's going to be core damage as well. And what about around the rub rail and windows?!? Ugh. Rub rails. Ugh. The rest I'm guessing is less a big deal if the glass is not springy. I'll order a PMM tonight.

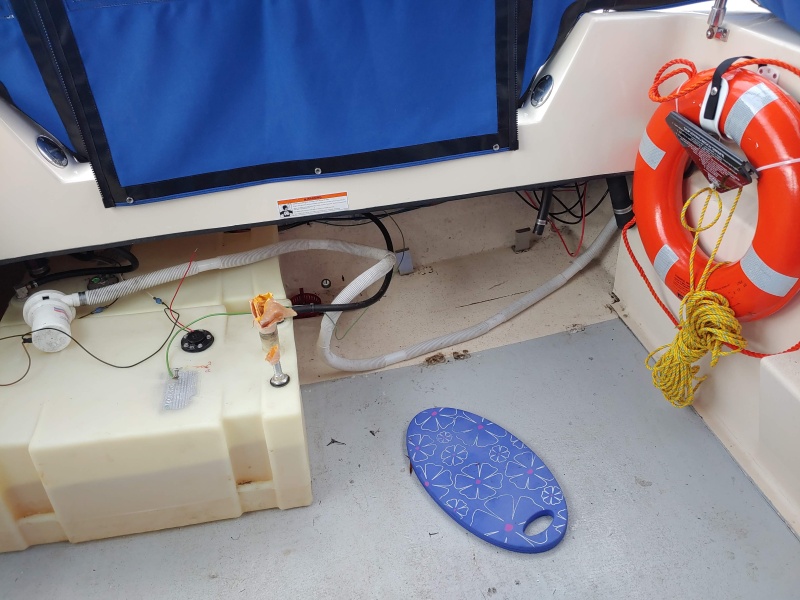

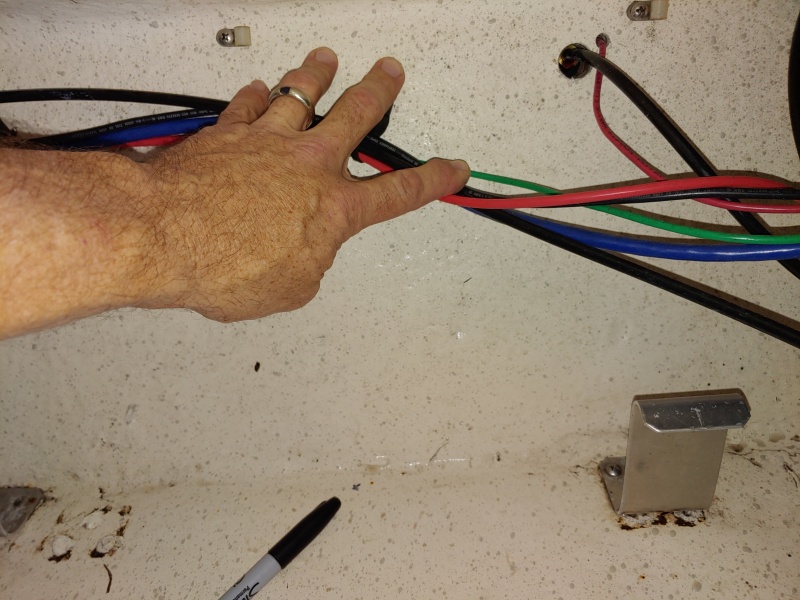

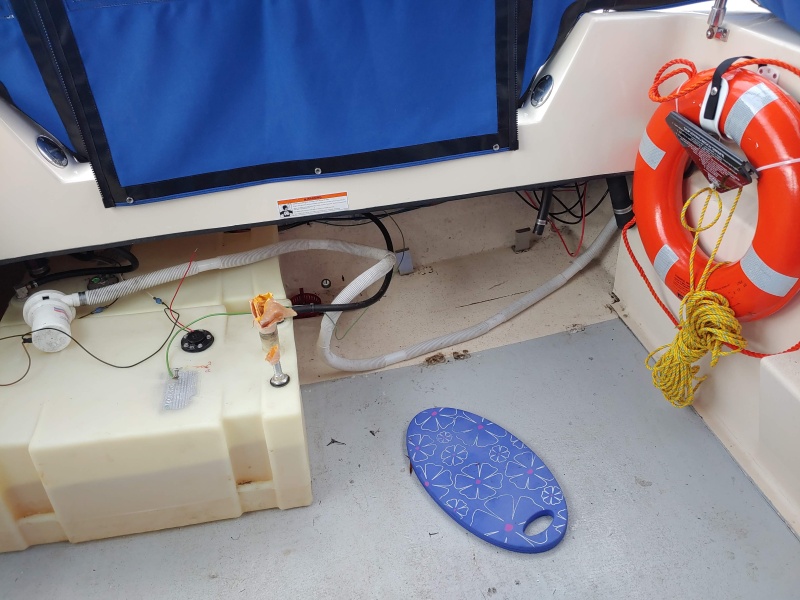

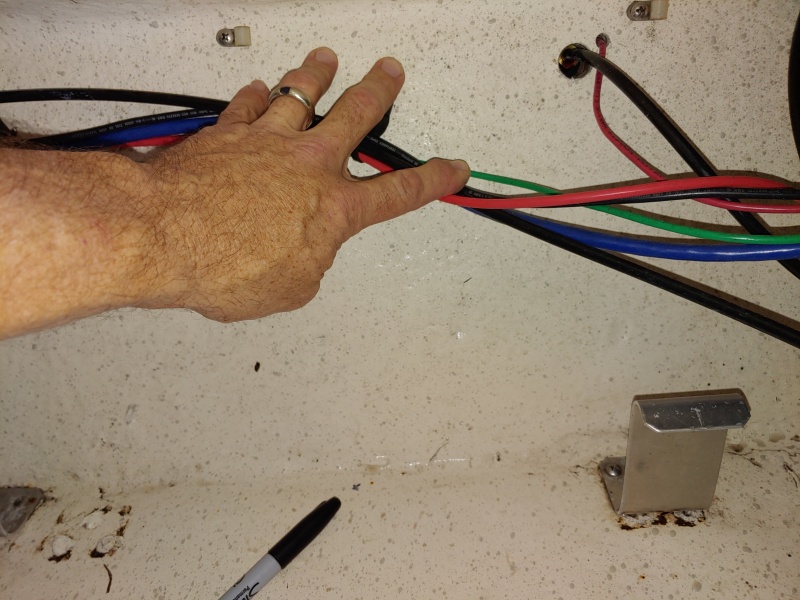

I slid the stbd gas tank out of the way and my rough guess is the outside hole is about where the sharpie is, but there's nothing showing from the cockpit and it feels solid. I really want to do this from the outside, that's why I made the bonus holes. But I can see how going from the inside is structurally preferable. Rats. I'll see what the folks at the factory say. This is the hard way to learn how to make an Alaskan bulkhead.

I'll keep everyone posted. Thanks for the info.

Last edited by bmcminn on Sat Nov 23, 2019 11:52 pm; edited 1 time in total |

|

| Back to top |

|

|

bmcminn

Joined: 20 Jul 2019

Posts: 65

City/Region: Bellingham

State or Province: WA

C-Dory Year: 1992

C-Dory Model: 19 Angler

Vessel Name: Polū

Photos: bmcminn

|

Posted: Sat Nov 23, 2019 11:46 pm Post subject: Posted: Sat Nov 23, 2019 11:46 pm Post subject: |

|

|

Here's a picture of the littlest helmsgirl, just to keep it light.

|

|

| Back to top |

|

|

localboy

Joined: 30 Sep 2006

Posts: 4656

City/Region: Lake Stevens via Honolulu

State or Province: WA

C-Dory Year: 2007

C-Dory Model: 25 Cruiser

Vessel Name: 'Au Kai (Ocean Traveler)

Photos: 'AU KAI

|

Posted: Sun Nov 24, 2019 2:08 am Post subject: Posted: Sun Nov 24, 2019 2:08 am Post subject: |

|

|

The wet balsa can be removed with a router bit in a drill. Remove it until it’s all dry, good wood. Hopefully it will only be an inch or so, max. Then wet the wood with epoxy resin followed by filling with thickened epoxy immediately. I’ve used West Sytems with hi density filler mixed to a peanut butter consistency. Once it goes off it’s hard as rock. Then re-bed the new hatches with something like 3M 4200/4400.

There shouldn’t be balsa around the windows or rub rail. Just glass. The balsa is only used in the bottom of the hull, roof, bow where your v-berth hatch is, top of the gunwales etc. the sides of the hull/cabin are just thick fiberglass, so you should have no issues with rot associated with windows. The bow hatch yes...like the lazarette hatches, is possible if it leaks.

Even the hole for our anchor windlass (rode) was exposed balsa. I gouged it out and used the thickened epoxy there too. Basically anywhere water can get into the balsa needs to be sealed off, or rot is possible. Even the screws that hold your fuel tanks down in the cockpit should be drilled oversized and filled with it. Same with your bilge pumps screws in the cockpit. The factory was less than thorough in this aspect of the builds. Here are pics of the same issue we had our our boat, just a different spot. You’ll see how I “gouged” out the rotted balsa and re-filled it all with epoxy. http://www.c-brats.com/modules.php?set_albumName=album2829&op=modload&name=gallery&file=index&include=view_album.php

Your daughter is beautiful.

_________________

"We can go over there...behind the 'little one'....."

Wife to her husband pointing @ us...from the bow of their 50-footer; Prideaux Haven 2013 |

|

| Back to top |

|

|

thataway

Joined: 02 Nov 2003

Posts: 20802

City/Region: Pensacola

State or Province: FL

C-Dory Year: 2007

C-Dory Model: 25 Cruiser

Vessel Name: thataway

Photos: Thataway

|

Posted: Sun Nov 24, 2019 10:31 am Post subject: Posted: Sun Nov 24, 2019 10:31 am Post subject: |

|

|

It certainly will be interesting to see what the "Factory Guys" say about this. While you are at it, ask them why they don't prevent these failures by putting solid core in the areas where any hole is drilled into the balsa core. This is not a problem unique to C Dorys. A very few builders have always put in solid glass or other solid core materials where any hull penetration is placed.

A few years back when a NDT scientist and my self were developing instrumentation to test core moisture and delamination, we cut up 20 hurricane damaged boats (Chain saw and skill saw) to do both testing and documentation. Some had no damage, but no penetrations. The ones which had solid core material (only a very low %) had no core damage. The instruments were never taken to market, since surveyors and most manufacturers didn't want to spring for the $2,000 for the instrument or take the time to learn a 21st century technology.

Please don't let anyone talk you into doing a repair on that boat from the outside. There are multiple reasons that it can be an issue down the line.

Expanding foam might work for a few very small areas--but I would not use it where you propose. It is not a barrier, and can absorb water. The balsa core damage will be limited, and as Local Boy says, rout out the core, (I prefer a Dremel tool, if necessary, get a flexible shaft, I have one which is only about 3/8" diameter, and will fit way back into core if necessary). I feel that the Dremel bits give a cleaner result, and are easier to control. However even an Allen wrench can be used, as well as a bent coat hanger.

I make my peanut butter consistency epoxy mix a little different. Paint in the neat epoxy to coat the balsa and sides of the glass above and below. Any screw penetration into a cored structure (deck, floor, or hull) should have an epoxy plug. The 22's have a core in the aft cabin bulkhead, but as noted all of the sides of cabin and hull are solid glass.

Keep us appraised of the work!

_________________

Bob Austin

Thataway

Thataway (Ex Seaweed) 2007 25 C Dory May 2018 to Oct. 2021

Thisaway 2006 22' CDory November 2011 to May 2018

Caracal 18 140 Suzuki 2007 to present

Thataway TomCat 255 150 Suzukis June 2006 thru August 2011

C Pelican; 1992, 22 Cruiser, 2002 thru 2006

Frequent Sea; 2003 C D 25, 2007 thru 2009

KA6PKB

Home port: Pensacola FL |

|

| Back to top |

|

|

bmcminn

Joined: 20 Jul 2019

Posts: 65

City/Region: Bellingham

State or Province: WA

C-Dory Year: 1992

C-Dory Model: 19 Angler

Vessel Name: Polū

Photos: bmcminn

|

Posted: Sun Nov 24, 2019 8:01 pm Post subject: Posted: Sun Nov 24, 2019 8:01 pm Post subject: |

|

|

OK, I'm going to do this myself. I want to see the core myself and I figure I can learn something new.

So I'm going to cut from the inside. Any reason not to go ahead and take one of those holes all the way through so I can find a corner? |

|

| Back to top |

|

|

South of Heaven

Joined: 15 Aug 2015

Posts: 1459

City/Region: Sharon

State or Province: MA

Photos: Blue Water

|

Posted: Sun Nov 24, 2019 8:07 pm Post subject: Posted: Sun Nov 24, 2019 8:07 pm Post subject: |

|

|

Don't freak out sir. The cockpit sole and the cockpit steps of my 25 were both compromised and had rotted core inside. Initially I was scared (and pissed!!) but upon further review I determined that the rot had not spread very far from the initial "holes".

You can definitely DIY it yourself. Take your time though. Don't skip any steps....

_________________

<><><> Jason <><><>

2005 Silverton 35 Motoryacht (Twin 385 Crusaders) (SOLD 6/20)

2000 Camano 31 Troll (Volvo TAMD41p) (SOLD 2/19)

2007 C Dory 25' Cruiser (200 hp Suzuki, sold 7/17)

2003 C Dory 19' Angler (80 hp Yamaha, sold 7/16)

1995 C Dory 16' Angler (40 hp Yamaha, sold 2/16) |

|

| Back to top |

|

|

thataway

Joined: 02 Nov 2003

Posts: 20802

City/Region: Pensacola

State or Province: FL

C-Dory Year: 2007

C-Dory Model: 25 Cruiser

Vessel Name: thataway

Photos: Thataway

|

Posted: Sun Nov 24, 2019 9:32 pm Post subject: Posted: Sun Nov 24, 2019 9:32 pm Post subject: |

|

|

| Quote: | | Any reason not to go ahead and take one of those holes all the way through so I can find a corner? |

I would choose the furthest aft and outboard hole, and came thru with that to the inside. Even if you have to cut the inner layer, right by the hull, this is not a problem, because you can bring the the glass up the side of the hull and make it a stronger repair. |

|

| Back to top |

|

|

localboy

Joined: 30 Sep 2006

Posts: 4656

City/Region: Lake Stevens via Honolulu

State or Province: WA

C-Dory Year: 2007

C-Dory Model: 25 Cruiser

Vessel Name: 'Au Kai (Ocean Traveler)

Photos: 'AU KAI

|

Posted: Sun Nov 24, 2019 9:49 pm Post subject: Posted: Sun Nov 24, 2019 9:49 pm Post subject: |

|

|

| Quote: | | However even an Allen wrench can be used... |

I've heard of this tool being used in this manner. I had a nice set of router bits of all shapes/sizes. On the drill, controlling it is easy. On a router, maybe not. The drill can control speed etc. The deepest I needed to clean out was about 5/8". I then hit clean, dry, white balsa. |

|

| Back to top |

|

|

bmcminn

Joined: 20 Jul 2019

Posts: 65

City/Region: Bellingham

State or Province: WA

C-Dory Year: 1992

C-Dory Model: 19 Angler

Vessel Name: Polū

Photos: bmcminn

|

Posted: Sun Nov 24, 2019 11:25 pm Post subject: Posted: Sun Nov 24, 2019 11:25 pm Post subject: |

|

|

Oh man 5/8" would be great. At least on the lazaret hatch a lot of it was wet back to 4" or 5". I just went at it with a long flat head screw driver until I was pulling out dry bits. In a few parts of the circumference it was nice within a 1/2" or so.

I'll start to re-epoxy this area tomorrow. If I finish it with 4400 do I still need to apply gelcoat around the inside edge? |

|

| Back to top |

|

|

san juanderer

Joined: 12 Aug 2014

Posts: 235

City/Region: Stanwood

State or Province: WA

C-Dory Year: 1990

C-Dory Model: 22 Angler

|

Posted: Mon Nov 25, 2019 11:05 am Post subject: Posted: Mon Nov 25, 2019 11:05 am Post subject: |

|

|

Frustrating right ! That the manufacturer would cut/ exposing the core material and NOT seal it correctly. Painting gel coat over the edge is NOT doing a proper structural seal.

What other short cuts might they be taking ?

Out of sight, is out of mind!

_________________

Cdory 22 Angler

SeaSport 24XL, Etec 250 hp (sold)

Rosborough RF246 (sold)

Commander 30 Sportfish (sold)

Olympic 26 XL (sold)

Glassply 19 (sold)

Olympic 23 (sold)

Bayliner 38 Motoryacht (sold)

Olympic 20 (sold)

Fiberform 16 (sold)

Olympic 18 (sold) |

|

| Back to top |

|

|

localboy

Joined: 30 Sep 2006

Posts: 4656

City/Region: Lake Stevens via Honolulu

State or Province: WA

C-Dory Year: 2007

C-Dory Model: 25 Cruiser

Vessel Name: 'Au Kai (Ocean Traveler)

Photos: 'AU KAI

|

Posted: Mon Nov 25, 2019 2:44 pm Post subject: Posted: Mon Nov 25, 2019 2:44 pm Post subject: |

|

|

| bmcminn wrote: | | ...do I still need to apply gelcoat around the inside edge? |

Nope. You won’t see it and the epoxy is gonna seal it all. The 4-5” really sucks. I would mix it a tad bit thinner and use a syringe to get to all the way inside the deepest parts. Otherwise filing that all by hand may be difficult. You might be able to get it in with a mixing stick. Wet the edges of the exposed balsa with just mixed epoxy & catalyst using a small brush so you have a wet edge when the thick resin is filled. |

|

| Back to top |

|

|

bmcminn

Joined: 20 Jul 2019

Posts: 65

City/Region: Bellingham

State or Province: WA

C-Dory Year: 1992

C-Dory Model: 19 Angler

Vessel Name: Polū

Photos: bmcminn

|

Posted: Wed Nov 27, 2019 4:08 pm Post subject: Posted: Wed Nov 27, 2019 4:08 pm Post subject: |

|

|

I pulled up some of the sole and the core is really wet. I've already got about a square foot. I'm going to keep looking until I get to some reasonable level of dryness and then I'll update with the situation re: the cockpit sole.

With the through holes in the hull I was recommended to use Gray Marine Tex instead of epoxy. It is expensive but I guess works well. The guy at the store however seemed uncertain about using it with fiberglass CSM. I had thought to use it just like epoxy (i.e. clean hole, fill hole, make concave, small diameter CSM and goop, big diameter CSM and goop, goop, sand, and glossy stuff) and figured the added thickness would help to hold upside down. But I'm going to wait to open it until someone (i.e. doc or localboy or micah - thanks!) chimes in.

With the lazaret, man it goes back so far that I really want to use expanding foam to within 3/4" of the edge and then finish with epoxy or Marine Tex.

OK. Except now after reading a bunch of stuff on Hull Truth, I'm going to go back and buy a bunch of epoxy and associated supplies. I think the guy just upsold me.

But I'm not going to open anything until I see what you all have to say. Hope you're having a good day! |

|

| Back to top |

|

|

Micahbigsur@msn.com

Joined: 27 May 2019

Posts: 484

City/Region: Big Sur

State or Province: CA

C-Dory Year: 2003

C-Dory Model: 25 Cruiser

Vessel Name: Sierra

Photos: Sierra

|

Posted: Wed Nov 27, 2019 4:54 pm Post subject: Posted: Wed Nov 27, 2019 4:54 pm Post subject: |

|

|

I like to make up my own West epoxy filler with a mixture that suits my present need, just an opinion, but I would use for a strong mix, high density, a bit of silica (for thixotropic, no sag properties) and microfibers. For a smooth finish leave out the fibers. No easy sanding micro-balloons below the waterline.

Good luck.

_________________

Micah Curtis and Dana, RN

2003 C-dory 25 Sierra, 200, 9.9 and 2.5 Suzukis

2012 R25 SC Sequoia (2015-2018)

1978 Folkes 38 SV Audacious (2006-2015)

Micah, KJ6GUF, Dana, KJ6GXG |

|

| Back to top |

|

|

localboy

Joined: 30 Sep 2006

Posts: 4656

City/Region: Lake Stevens via Honolulu

State or Province: WA

C-Dory Year: 2007

C-Dory Model: 25 Cruiser

Vessel Name: 'Au Kai (Ocean Traveler)

Photos: 'AU KAI

|

Posted: Wed Nov 27, 2019 5:26 pm Post subject: Posted: Wed Nov 27, 2019 5:26 pm Post subject: |

|

|

| Can't say not to use the expanding foam finished off with thick epoxy, but I have limited knowledge and no experience using it. There was a poster on TF that used it on his deck of his 30+ yr old Taiwan trawler. It wasn't just the Home Depot stuff you purchase for sealing windows etc though. It was this stuff: https://injectadeck.com/ |

|

| Back to top |

|

|

bmcminn

Joined: 20 Jul 2019

Posts: 65

City/Region: Bellingham

State or Province: WA

C-Dory Year: 1992

C-Dory Model: 19 Angler

Vessel Name: Polū

Photos: bmcminn

|

Posted: Wed Nov 27, 2019 7:00 pm Post subject: Posted: Wed Nov 27, 2019 7:00 pm Post subject: |

|

|

OK That inject a deck looks interesting because...

However, there's no part of the deck that feels soft or squishy at all. I don't really know what to do. You can see where the core is just mushy junk that I can pull out vs more solid but still wet material. So do I fix the holes in the hull, throw a piece of plywood on this, fish through January, and then pull the entire sole later this spring?

Or do I get a PMM and search for more rotten core, drill, and use that crazy inject-a-deck.

Right now I'm gonna use some saltwater to do some brining. Back here later.

|

|

| Back to top |

|

|

|

Search

Search Private Messages

Private Messages Profile

Profile Log in

Log in Register

Register Help

Help